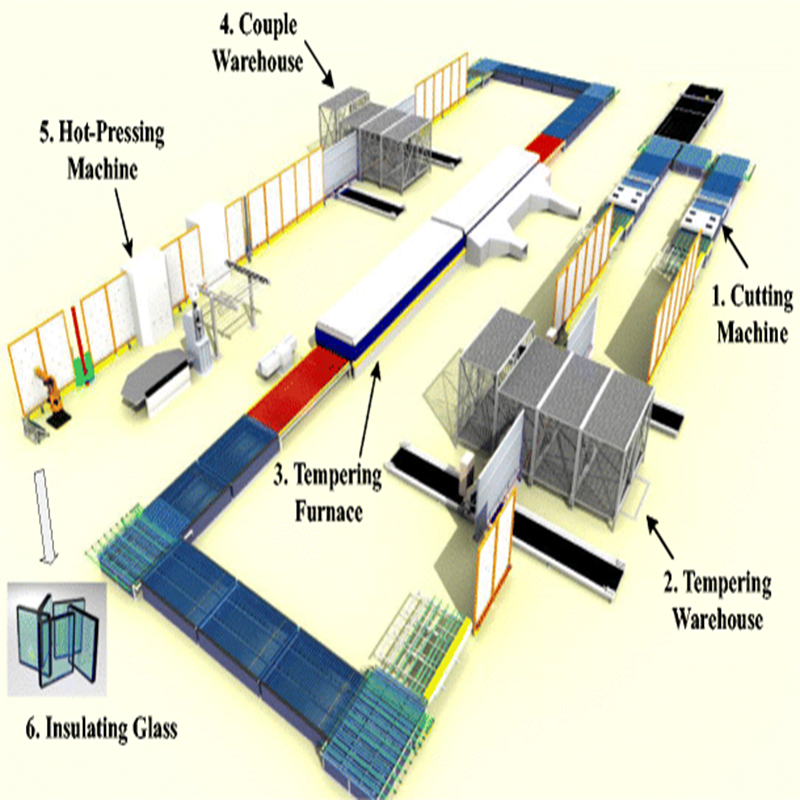

Hollow glass, also known as insulating glass, consists of two or more panes of glass sealed together to create an air space, enhancing thermal insulation and soundproofing. Below is a detailed overview of the process involved in transforming ordinary glass into hollow glass.

1. Surface Treatment

After cutting, the glass undergoes surface treatment, which includes:

Edge Polishing: The edges of the glass are polished to remove roughness, ensuring a smooth finish that minimizes the risk of injury.

Cleaning: The glass surfaces are thoroughly cleaned using specialized cleaning agents to eliminate any dust, grease, or residues that could interfere with the sealing process.

2. Assembly of Hollow Structure

The next step involves assembling the glass panes to create the hollow structure. The panes are held apart using spacer bars, typically made of aluminum, which are placed around the perimeter of the glass. The space between the panes, typically ranging from 6mm to 20mm, is carefully controlled to optimize thermal performance.

3. Gas Filling

To enhance the insulating properties of the hollow glass, the space between the panes filled with an inert gas, such as argon. This step is crucial for reducing thermal conductivity and sound transmission. During this process, care is taken to ensure there are no air bubbles or leaks, as these can compromise the performance of the final product.

4. Sealing

Once the assembly is complete, a high-quality sealing adhesive is applied around the edges of the glass panes. This sealant prevents the ingress of moisture and air, ensuring the integrity of the insulating layer. The quality of this seal is vital for the longevity and effectiveness of the hollow glass.

5. Inspection and Packaging

Finally, the finished hollow glass undergoes rigorous quality inspection, checking for factors such as pressure resistance, light transmission, and thermal insulation properties. Any panels that do not meet the required standards are rejected. Once they pass inspection, the glass panels are carefully packaged to prevent damage during transportation.

Conclusion

The process of manufacturing hollow glass involves multiple stages, each requiring precision and control to ensure high-quality results. Due to its excellent thermal and acoustic insulation properties, hollow glass is widely used in modern architecture, contributing to energy efficiency and comfort in living and working environments.