Pattern glass, also known as textured glass, is produced through a specialized process that creates unique surface textures for decorative applications.

During production, molten glass is passed through patterned rollers or molds, imprinting textures onto the surface. This process is widely used for semi-transparent decorative glass, like the popular "Moru" style.

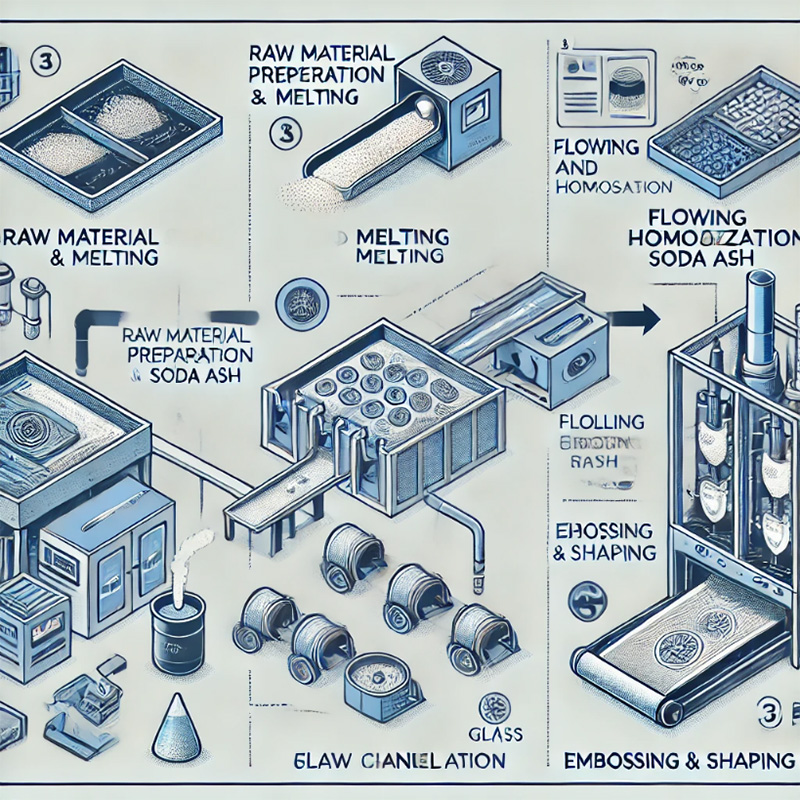

1. Raw Material Preparation and Melting

High-purity silica sand, soda ash, limestone, and small amounts of alumina and barium oxide are combined to form the glass. This mixture is heated in a furnace to around 1400°C (2552°F), melting into a uniform, bubble-free liquid.

2. Flowing and Patterning

The molten glass flows through a controlled channel, maintaining an even temperature. It then reaches a rolling machine with patterned rollers that emboss textures such as Moru, diamond, or grid patterns. Roller temperature and speed are carefully managed to ensure consistent textures and thickness.

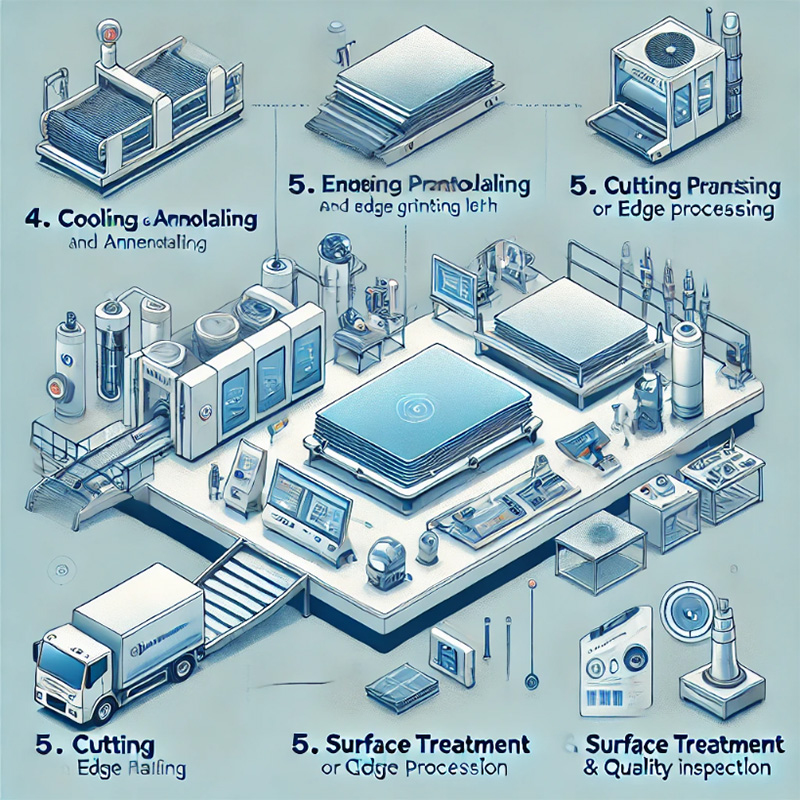

3. Cooling and Annealing

After patterning, the glass undergoes an initial cooling to set the texture. It then enters an annealing furnace, where it cools gradually to relieve internal stress, enhancing durability. A controlled cooling rate is essential, especially for thicker glass, to minimize breakage risks.

4. Cutting, Edge Processing, and Final Treatment

Once cooled, the glass is cut to size and edges are smoothed for safety and aesthetics. Optional surface treatments, such as coatings for durability or color, may be applied. Each piece is then inspected to ensure texture clarity, flatness, and strength, meeting quality standards.