Silk screen printing glass is a type of glass decorated with printed patterns or colors, combining aesthetic appeal with functionality. It is widely used in architecture, interior decoration, appliances, and even the automotive industry.

Basic Process of Silk Screen Printing Glass

The production of silk screen printing glass involves the following steps:

1.Design and Screen Preparation: The desired pattern is designed and then created as a screen template.

2.Glass Cleaning: The glass surface is cleaned thoroughly to ensure that the ink adheres uniformly.

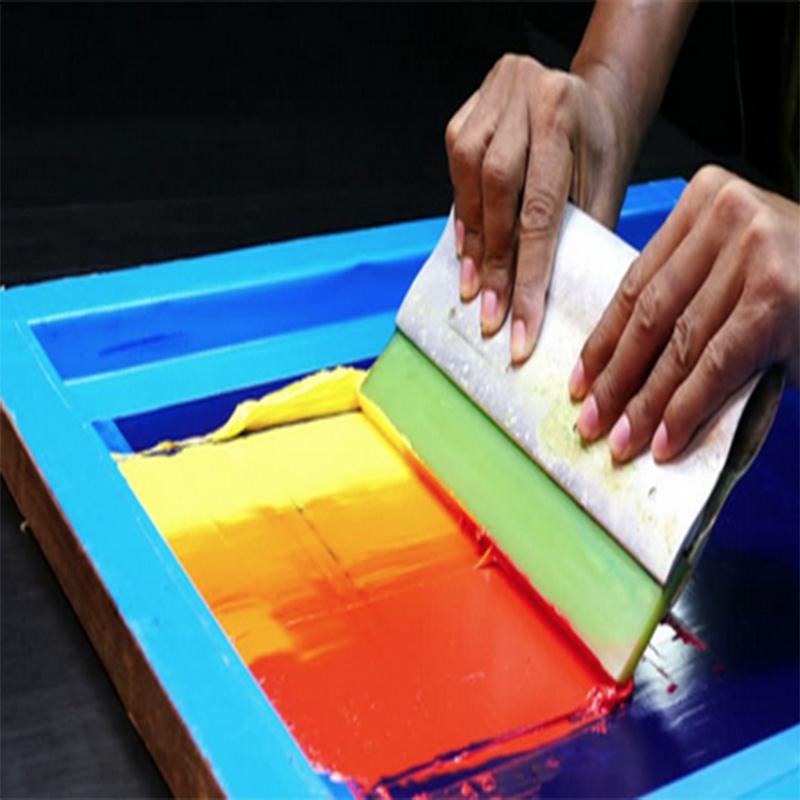

3.Screen Printing: Ink is applied to the glass surface through the screen, transferring the design.

4.Drying or Sintering: The ink is cured onto the glass surface, either through drying or sintering, depending on the specific technique used.

Applications of Silk Screen Printing Glass

Silk screen printing glass has a wide range of applications across industries, owing to its versatility in design and functionality:

Architectural Decoration: Used in curtain walls, partitions, and windows to enhance aesthetics and brand identity.

Interior Design: Provides decorative effects and privacy in spaces such as glass partitions and shower enclosures.

Thermal Sintered Screen Printing and Ambient Cured Screen Printing offer distinct benefits for different applications. Thermal Sintered Screen Printing involves high-temperature firing, for exceptional weather resistance, durability, and stability—ideal for building facades and other high-durability needs.

In contrast, Ambient Cured Screen Printing uses lower temperatures and UV inks, offering vibrant colors, intricate detail, and compatibility with various glass types, making it a cost-effective choice for indoor decor, and office partitions.