Insulated glass and vacuum glass are two common high-performance insulating materials widely used in windows, curtain walls, and building facades. While their core function is to provide better insulation, they differ significantly in structure, performance, and application areas.

1. Structural Differences

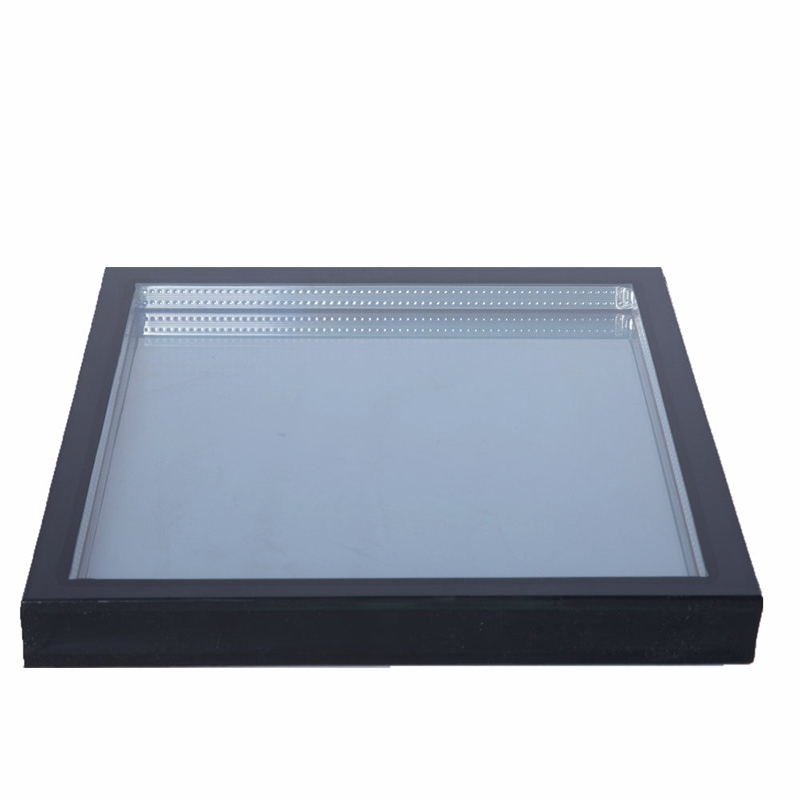

Insulated glass consists of two or more layers of glass with a gap between them, typically filled with dry air or gases like argon. This gas layer works to slow down the transfer of heat, enhancing its insulating properties.

In contrast, vacuum glass features a high vacuum layer between two glass panes, with virtually no air molecules. This structure greatly reduces heat transfer through conduction and convection, providing more efficient insulation.

2. Insulation Performance

Vacuum glass offers superior insulation performance compared to insulated glass. Because the vacuum layer almost completely blocks the transmission of heat, vacuum glass is one of the most effective insulating materials available.

While insulated glass also effectively reduces heat transfer, its gas layer is not entirely impervious to heat conduction, so its insulation performance is relatively limited and is typically used in applications where insulation requirements are not as extreme.

3. Weight and Thickness

Insulated glass tends to be thicker, usually ranging from 10mm to 20mm, and because of the gas layer between the panes, it is also heavier.

On the other hand, vacuum glass has a thinner structure, typically between 5mm and 10mm, and is lighter in weight, making it suitable for architectural designs that require thin-profile windows.

4. Cost Differences

Due to the complex manufacturing process and the need to maintain a high vacuum between the glass layers, vacuum glass is more expensive to produce. Therefore, it is typically used in high-end energy-efficient buildings, specialized windows, and other applications where superior insulation is required.

Insulated glass, on the other hand, has a simpler manufacturing process, making it more cost-effective and widely used in residential buildings, commercial spaces, and other standard applications.

5. Application Areas

Insulated glass, with its good thermal and sound insulation properties, is commonly used in windows, curtain walls, and facades of residential, office, and other commercial buildings.

Vacuum glass is more commonly applied in buildings that require high energy efficiency and comfort, particularly in projects with extremely high insulation standards, such as luxury residences, commercial buildings, and certain specialized industrial facilities.

Conclusion

If you're on a budget and have moderate insulation needs, insulated glass remains a highly cost-effective choice. For projects that require exceptional insulation performance, particularly in high-end buildings, vacuum glass offers superior results.