Fire-resistant glass is a type of specialized safety glass designed to prevent the spread of fire and protect people and property during a fire event. This glass is engineered to withstand high temperatures and maintain its integrity for a specified period, thereby creating a barrier that slows down the transfer of heat and prevents the passage of flames and smoke.

Types of Fire-Resistant Glass and Their Manufacturing Processes

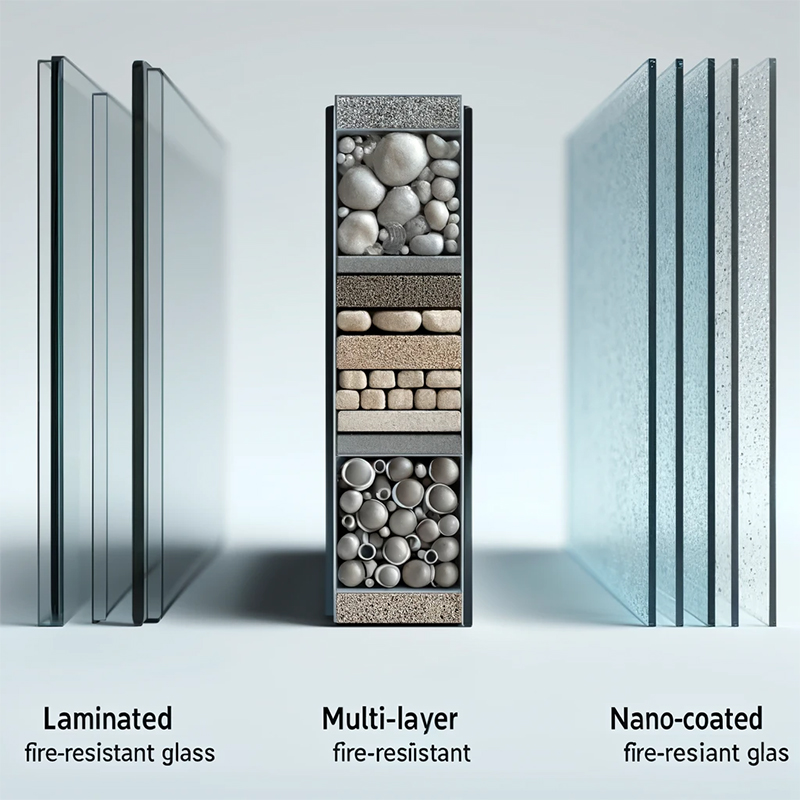

1. Laminated Fire-Resistant Glass

This type of fire-resistant glass is produced by sandwiching a special fire-resistant interlayer or gel between two panes of glass. The fire-resistant interlayer has the property of expanding when exposed to high temperatures, forming an insulating barrier that slows down the transmission of flames and heat.

Manufacturing Process: Two sheets of tempered or standard glass are combined using a heat and pressure bonding technique. The interlayer can be a transparent fire-resistant gel or a specially designed film.

2. Multi-Layer Fire-Resistant Glass

Multi-layer fire-resistant glass typically consists of several layers of glass and fire-resistant materials. The interlayers, which may include mineral compounds, metal oxides, or specialized coatings, prevent the spread of fire.

Manufacturing Process: Different thicknesses of glass sheets are bonded with fire-resistant intermediate materials, such as minerals or gypsum, to create a multi-layered structure.

3. Nano-Coated Fire-Resistant Glass

Nano coating is a thin, specialized layer made from nanomaterials that offers exceptional insulation and fire resistance at high temperatures. By applying this coating evenly to the surface of the glass, it enhances the glass's protective capabilities. Common nanomaterials include titanium dioxide (TiO2), zinc oxide (ZnO), and composite metal oxides.

Manufacturing Process: The glass substrate is prepared and cleaned, and the nano coating solution is applied using spraying, dipping, or spinning techniques. The coating is then cured through low-temperature drying or UV curing to ensure stability.