The evolution of glass printing technology has transformed how we utilize glass in design and architecture, allowing for more artistic expression beyond its conventional use. In this context, Digital Printing on Glass and UV Printing on Glass are two significant methods, each with its own advantages, limitations, and applications.

Overview of Glass Printing Technology

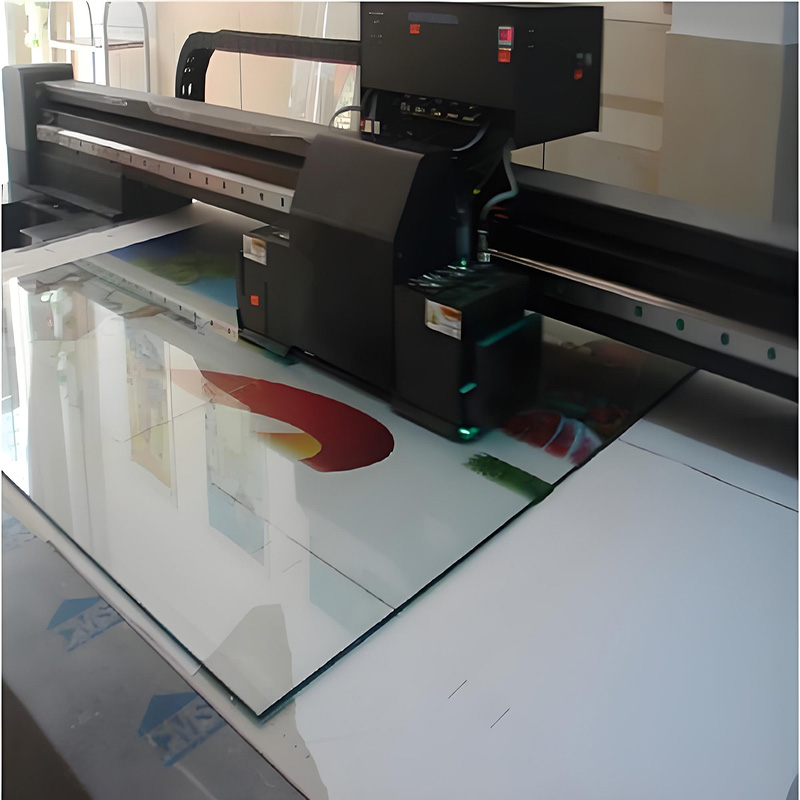

Glass printing involves the application of patterns, text, or images onto glass surfaces using specialized inks and equipment. This technique enables designers to create unique visual effects, enhancing both the aesthetic and functional characteristics of glass. Digital printing on glass and UV printing on glass are two prominent methods, each offering distinct benefits.

Digital Printing on Glass

Definition

Digital Printing on Glass is a process in which images or patterns are directly printed onto the glass surface using digital printing technology. This can involve various types of inks, including aqueous inks and UV-curable inks.

Advantages

High Resolution: Digital printing allows for detailed and vibrant images, making it ideal for intricate designs.

Flexibility: It is well-suited for small-batch production and customization, catering to individual design preferences.

No Need for Stencils: Unlike traditional printing methods, digital printing eliminates the need for creating stencils, streamlining the production process.

Application Scenarios

Digital printing on glass is commonly used for custom artwork, interior décor, signage, and other applications requiring personalized designs.

Heat Treatment

Digital printing often requires heat treatment to enhance ink adhesion and durability on the glass surface.

UV Printing on Glass

Definition

UV Printing on Glass is a process in which UV-curable inks are applied to the glass surface and instantly cured by UV light, creating a strong and durable print.

Advantages

Durability: The UV-cured inks form a hard, resistant layer on the glass, offering excellent durability against scratches and fading.

Versatility: This method can print on various glass shapes and sizes, providing flexibility for unique designs.

Application Scenarios

UV printing on glass is typically used for advertisements, displays, decorative elements, and other projects requiring rapid production or durability.

Heat Treatment

UV printing is commonly performed on tempered glass, which enhances the overall strength and durability of the printed design.

| Feature | Digital Printing on Glass | UV Printing on Glass |

| Printing Method | Direct inkjet printin | UV-curable ink application |

| Durability | High, very resistant to wear | Good |

| Resolution | High resolution and detail | Moderate to high resolution |

| Flexibility | High, great for custom designs | High, accommodates various shapes |

| Application Scope | Advertising, displays, durable products | Art, interior décor, signage |

| Heat Treatment | Often required for durability | Performed on tempered glass |

Conclusion

Digital printing on glass and UV printing on glass each present unique advantages and applications in the world of glass printing technology. The choice between these methods should be guided by the specific requirements of the project, including production volume, design complexity, and durability needs. As glass printing technology continues to evolve, both methods will play an essential role in future design innovations.