Glass is a widely used material in architecture due to its transparency, aesthetic appeal, and energy efficiency. However, regular glass is prone to shattering under impact, posing a safety hazard. To address this issue, the laminated glass process was developed.

This technique involves bonding multiple layers of glass with interlayers of plastic film, significantly enhancing the glass’s strength, safety, soundproofing, and insulation properties. Laminated glass plays a critical role in modern construction, combining beauty and functionality.

What is Laminated Glass?

Laminated glass consists of two or more layers of glass with a plastic interlayer (typically PVB, SGP, or EVA) sandwiched between them. These layers are bonded together under heat and pressure, creating a strong, durable material.

Unlike regular glass, laminated glass does not shatter into dangerous shards upon impact. Instead, the interlayer holds the broken pieces together, significantly improving safety. Laminated glass also offers enhanced soundproofing, UV resistance, and impact resistance, making it suitable for a wide range of applications, including building facades, windows, skylights, and automotive windshields.

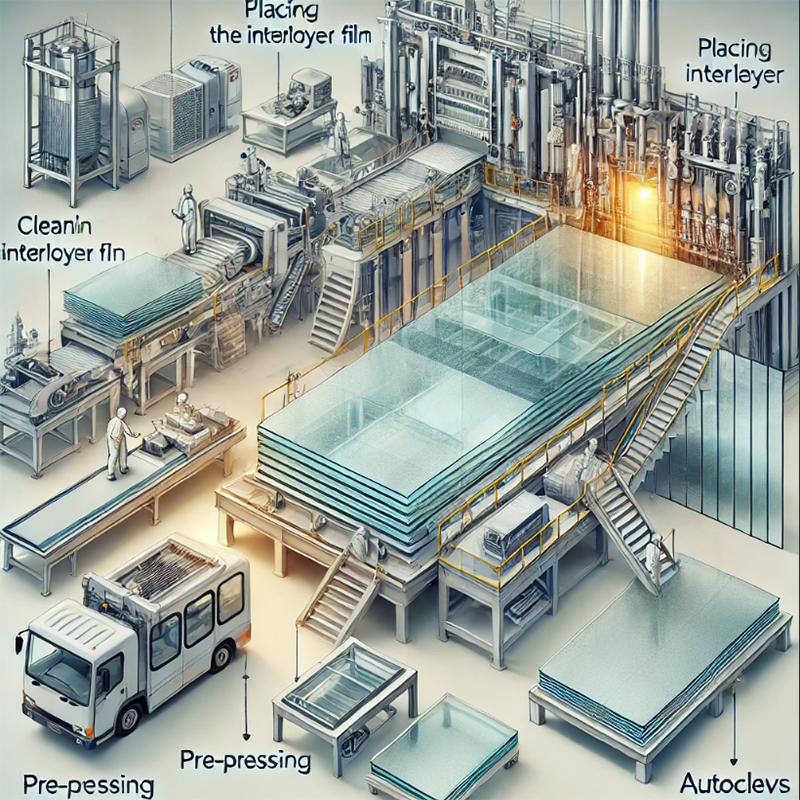

The Laminated Glass Process: Step-by-Step

Laminating glass involves several key stages to ensure that the interlayer and glass bond perfectly without air bubbles or imperfections. Below is a detailed breakdown of each step.

1. Cleaning and Preparation of Glass

The first step in the process is thoroughly cleaning the glass. Any dust or contaminants on the surface can lead to imperfections, such as bubbles or cloudiness, in the final product. Special cleaning equipment is used to ensure the glass is spotless and ready for the next stages.

2. Selection and Placement of the Interlayer

The interlayer plays a critical role in the laminated glass’s performance. PVB (polyvinyl butyral) is the most commonly used material due to its excellent adhesion and flexibility, which also provides soundproofing and UV resistance.

Depending on the specific use, alternatives like SGP (ionoplast interlayer) or EVA (ethylene-vinyl acetate) may be chosen. The interlayer is carefully placed between the layers of glass to ensure a smooth, uniform bond.

3. Pre-pressing

After the interlayer is placed between the glass layers, the glass is transferred to a pre-press machine. In this step, a vacuum is applied to remove any air trapped between the glass and the interlayer, followed by heating to soften the interlayer. This initial bonding phase ensures the layers adhere properly and prepares the glass for the final step in the autoclave.

4. Autoclaving

The pre-pressed glass is then placed into an autoclave, a high-pressure, high-temperature chamber. Inside the autoclave, the glass is subjected to temperatures of around 120-140°C and pressure of about 1.0-1.2 MPa.

This process ensures the complete fusion of the interlayer and glass, resulting in a flawless laminated product. The autoclave process typically takes several hours to ensure the laminated glass achieves its optimal strength and clarity.

5. Cooling and Quality Inspection

Once the glass exits the autoclave, it is gradually cooled. After cooling, the laminated glass is carefully inspected for defects such as bubbles, distortions, or imperfections. Only glass that passes stringent quality control checks is approved for use.

Key Advantages of Laminated Glass

1.Enhanced Safety

One of the biggest advantages of laminated glass is its enhanced safety. When struck with force, laminated glass cracks but does not shatter, as the interlayer keeps the glass intact. This makes it a preferred choice for exterior building applications, such as facades, skylights, and glass balustrades, where safety is a priority.

2. Excellent Soundproofing

The plastic interlayer also contributes to the soundproofing qualities of laminated glass, as it helps dampen sound waves. This makes it an ideal material for use in noisy urban environments or buildings that require noise insulation, such as offices, homes, and conference rooms.

3. Impact and Explosion Resistance

Laminated glass can be engineered for greater impact resistance by increasing the thickness of the glass layers or by using stronger interlayers. This makes it ideal for high-security environments, such as banks, jewelry stores, and government buildings, where both burglary and explosion resistance are critical.

Innovative Applications of Laminated Glass

Laminated glass is not just about safety—it has become an integral part of modern architectural design. By incorporating colored interlayers, metal meshes, or patterns into the laminated glass, designers can create stunning visual effects while maintaining the glass’s functional benefits. This type of decorative laminated glass is used for both interior and exterior applications, adding a creative touch to spaces.

Moreover, laminated glass can be combined with smart technologies, such as switchable glass or photovoltaic glass. Switchable glass allows the transparency of the glass to change with light or temperature, while photovoltaic glass can generate electricity from sunlight, contributing to energy-efficient buildings.

Conclusion

Laminated glass is a highly versatile material with applications that span from safety to design and sustainability. Its durability, soundproofing, and UV protection properties make it ideal for modern architecture, while its ability to incorporate innovative features such as decorative interlayers or smart glass technology ensures it remains at the forefront of building trends. As technology advances, the use of laminated glass will likely expand further, shaping the future of safer and greener buildings.