Production Method of Artistic Hot Melt Glass and Quality Inspection Method of Embossed Glass

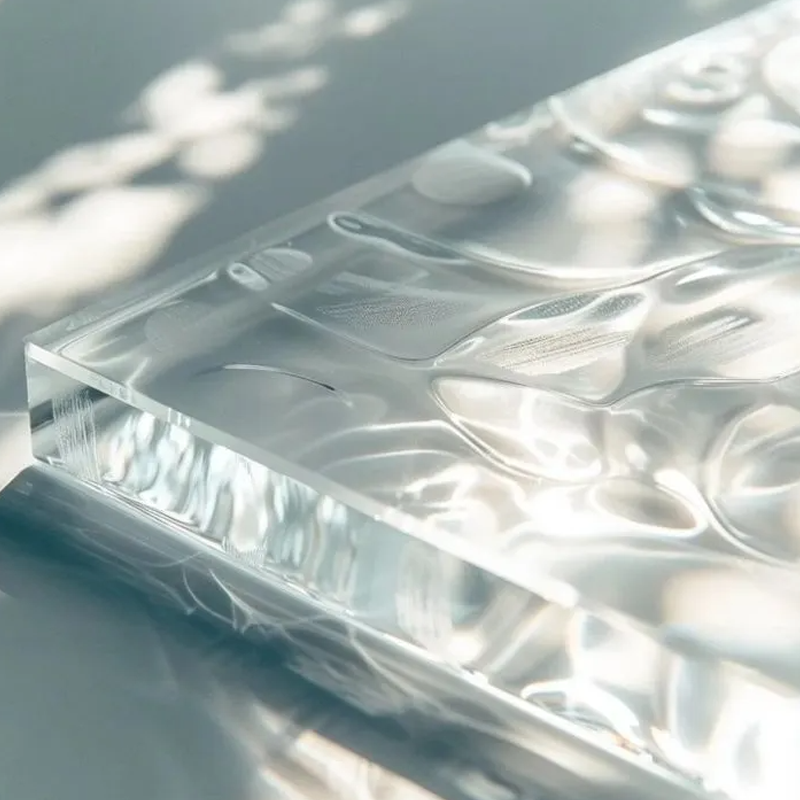

In the modern decoration field, artistic glass has become an important element of space decoration due to its unique aesthetic value and diverse forms of expression. Among them, hot melt glass relies on its smooth shape and rich texture, while embossed glass relies on its unique patterns and good privacy, both occupying an important position. This article will elaborate on the production method of artistic hot melt glass and the quality inspection method of embossed glass, providing references for relevant practitioners and enthusiasts.

I. Production Method of Artistic Hot Melt Glass

Artistic hot melt glass is a processing technology that melts glass raw materials at high temperatures and endows the glass with artistic texture through mold shaping, manual carving and other methods. Its production process is rigorous and creative, mainly including the following core steps:

(I) Selection and Pretreatment of Raw Materials

1. Raw Material Selection: The core raw materials for making artistic hot melt glass are borosilicate glass or ordinary soda-lime glass, which need to be selected according to the use and aesthetic requirements of the finished products. Borosilicate glass has strong heat resistance and is suitable for making artistic hot melt glass products used in high-temperature environments; soda-lime glass has high transparency and moderate cost, and is a commonly used raw material for decorativeartistic hot melt glass. At the same time, colorants can be added according to design requirements. The colorants should be high-temperature resistant and uniformly colored inorganic colorants to ensure the color stability of the hot melt glass finished products.

2. Pretreatment Process: First, cut the glass raw materials, and accurately cut them with a glass cutting machine according to the size of the finished product to ensure that the cut is flat and free of burrs. Then, edge grinding is carried out, and the edges of the cut glass are polished with an edge grinding machine to avoid breakage in subsequent processing due to sharp edges, and at the same time improve the safety and aesthetics of artistic hot melt glass. Finally, clean the glass surface to remove dust, oil stains and other impurities on the surface, preventing these impurities from affecting the texture and transparency of hot melt glass during the melting process.

(II) Mold Making and Preparation

The mold is the key to determining the shape of artistic hot melt glass. According to the design drawings, the mold material can be heat-resistant gypsum, ceramics or metal. Heat-resistant gypsum has low cost and strong plasticity, and is suitable for making molds for complex-shaped hot melt glass; metal molds have high strength and long service life, and are suitable for mass production of standardized artistic hot melt glass products.

After the mold is made, it needs to be dried and preheated. Drying treatment can remove the moisture in the mold, avoiding bubbles or cracks on the glass surface caused by the evaporation of moisture at high temperatures; preheating treatment is to heat the mold to a certain temperature in advance (usually 200-300℃), reducing the temperature difference between the mold and the high-temperature glass, and preventing the glass from breaking due to uneven thermal expansion and contraction.

(III) Melting and Shaping

1. Melting Process: Put the pretreated glass raw materials into a tempering furnace and gradually heat up to 800-1200℃. During the heating process, the heating rate must be strictly controlled to avoid the glass breaking due to sudden temperature rise. When the glass reaches the molten state, it will present a viscous liquid form. At this time, according to the design requirements, manual stirring, adding decorative particles and other methods can be used to increase the texture level of artistic hot melt glass.

2. Shaping Operation: Pour the molten glass liquid into the preheated mold, or make the glass fit the shape of the mold through mechanical pressing, manual shaping and other methods. For complex artistic hot melt glass shapes, layered melting and gradual shaping can be adopted to ensure that each layer of glass is fully fitted, avoiding delamination, hollowing and other problems. During the shaping process, the operator must accurately control the flow rate and shaping force of the glass liquid to ensure that the shape of the finished product meets the design requirements.

(IV) Annealing and Post-Processing

1. Annealing Treatment: The shaped hot melt glass needs to be annealed, which is a key process to improve the stability of the glass. Put the shaped glass into an annealing furnace and cool it slowly. The cooling rate should be adjusted according to the thickness and shape complexity of the glass. Usually, it takes several hours to dozens of hours to cool from high temperature to room temperature. Annealing treatment can eliminate the internal stress of the glass, avoid the glass breaking due to stress release in subsequent use, and ensure the service life of artistic hot melt glass.

2. Post-Processing Process: After annealing, polish and buff the finished artistic hot melt glass to improve the surface finish. For finished products with special requirements, sandblasting, engraving, coating and other processing can also be carried out to further enhance the decorative effect of artistic hot melt glass. Finally, conduct quality inspection on the finished products and remove unqualified products.

II. Quality Inspection Method of Embossed Glass

II. Quality Inspection Method of Embossed Glass

Embossed glass is a type of artistic glass pressed by pattern rollers when the glass is in a molten state. Its quality directly affects the decorative effect and use safety. The quality inspection of embossed glass needs to cover multiple dimensions such as appearance, size and physical properties. The specific inspection methods are as follows:

(I) Appearance Quality Inspection

1. Pattern Integrity Inspection: Place the embossed glass in a well-lit environment and observe it visually at a distance of 50-100cm from the glass. The patterns of qualified embossed glass should be clear, complete, without missing flowers, broken flowers, deformation and other problems. For mass-produced embossed glass, samples should be randomly selected for inspection to ensure the consistency of the patterns.

2. Surface Defect Inspection: Observe the surface of embossed glass with the naked eye or a magnifying glass to check for bubbles, sand grains, scratches, cracks, impurities and other defects. The diameter of bubbles should not be greater than 0.5mm, and the number of bubbles per square meter should not exceed 3; sand grains, impurities, etc. should have no obvious protrusions and should not affect the flatness of the glass; the length of scratches should not be greater than 5mm, and the number of scratches per square meter should not exceed 2. If the above defects exist and exceed the standard range, it is judged as an unqualified product.

3. Color Uniformity Inspection: For colored embossed glass, it is necessary to check whether its color is uniform and consistent. Splice multiple pieces of embossed glass of the same batch together and observe the color difference visually. No obvious color difference is qualified. If there are local discoloration, excessive color difference and other problems, it will affect the decorative effect of embossed glass and need to be judged as unqualified.

(II) Dimensional Deviation Inspection

1. Length and Width Inspection: Measure the length and width of embossed glass with a tape measure or a straightedge. The measurement points should be the four corners and the midpoints of the four sides of the glass, totaling 8 measurement points. According to national standards, the length and width deviation of embossed glass should not exceed ±3mm/m, and the total deviation should not exceed ±10mm. If the measurement result exceeds the deviation range, it is necessary to carry out cutting correction or judge as unqualified.

2. Thickness Deviation Inspection: Use a micrometer to select 10 measurement points at different positions of embossed glass to measure the thickness of the glass. The thickness deviation of embossed glass should not exceed ±0.2mm, and the thickness difference of the same piece of glass should not exceed 0.1mm. Uneven thickness will affect the strength and optical performance of the glass, and unqualified products need to be eliminated.

3. Flatness Inspection: Lay the embossed glass flat on a horizontal inspection platform, and check the flatness of the glass with a level and a feeler gauge. The maximum gap between the glass and the platform should not exceed 0.5mm/m, and the total gap should not exceed 1mm. If the gap is too large, it indicates that the flatness of the glass is poor, which will affect the installation effect and use safety, and needs to be judged as unqualified.

(III) Physical Performance Inspection

1. Strength Inspection: Impact resistance test is used to detect the strength of embossed glass. Fix the glass on the test device, let a steel ball of specified weight fall freely from a specified height, and observe whether the glass breaks. Qualified embossed glass should be able to withstand the impact of specified strength, without breaking or only producing a small number of cracks, which will not affect the overall structural stability. If the glass breaks or shatters on a large scale, it is judged as strength unqualified.

2. Light Transmission Performance Inspection: Use a light transmittance tester to measure the light transmittance of embossed glass. The light transmittance of ordinary embossed glass should not be less than 70%, and the light transmittance of colored embossed glass should be determined according to design requirements, and the light transmittance deviation of products of the same batch should not exceed ±3%. Failure to meet the light transmittance requirements will affect the lighting effect of the space and need to be judged as unqualified.

3. Heat Resistance Inspection: Put the embossed glass into a constant temperature box, gradually heat it up to 200℃, keep it warm for 2 hours, then cool it naturally to room temperature, and observe whether the glass has cracks, deformation and other problems. Qualified embossed glass should have no obvious changes, and its heat resistance meets the use requirements. If there are cracks, deformation and other situations, it indicates that the heat resistance of the glass is poor and it is not suitable for high-temperature environments.

(IV) Packaging and Marking Inspection

1. Packaging Inspection: Check whether the packaging of embossed glass is firm and standardized. The packaging materials should be shockproof and moisture-proof materials, such as foam, cartons, wooden boards, etc., to ensure that the glass is not damaged during transportation and storage. A separator should be placed between each piece of glass to avoid scratches caused by mutual friction. The packaging should be marked with product name, specification, quantity, manufacturer, production date and other information.

2. Marking Inspection: Check whether the embossed glass products have qualified marks. The qualified marks should include product standard number, quality grade, inspector code and other information. Products without qualified marks or incomplete marking information are regarded as unqualified products and shall not leave the factory for sale.

III. Conclusion

The production of artistic hot melt glass requires precise control of each process. From raw material selection to finished product post-processing, it directly affects the aesthetic value and use performance of the product; the quality inspection of embossed glass needs to fully cover multiple dimensions such as appearance, size and physical properties to ensure that the product meets the standard requirements. As important categories of artistic glass, the quality improvement of hot melt glass and embossed glass can not only promote the development of the decoration industry, but also create a more beautiful and safe living space for people. Relevant practitioners should strictly follow the production specifications and inspection standards, continuously optimize the process, improve product quality, and help the continuous progress of the artistic glass industry.

hot melt glasshot melt glasshot melt glasshot melt glasshot melt glasshot melt glassartistic hot melt glass