How Many Main Production Methods Are There for Coated Glass? Do You Know?

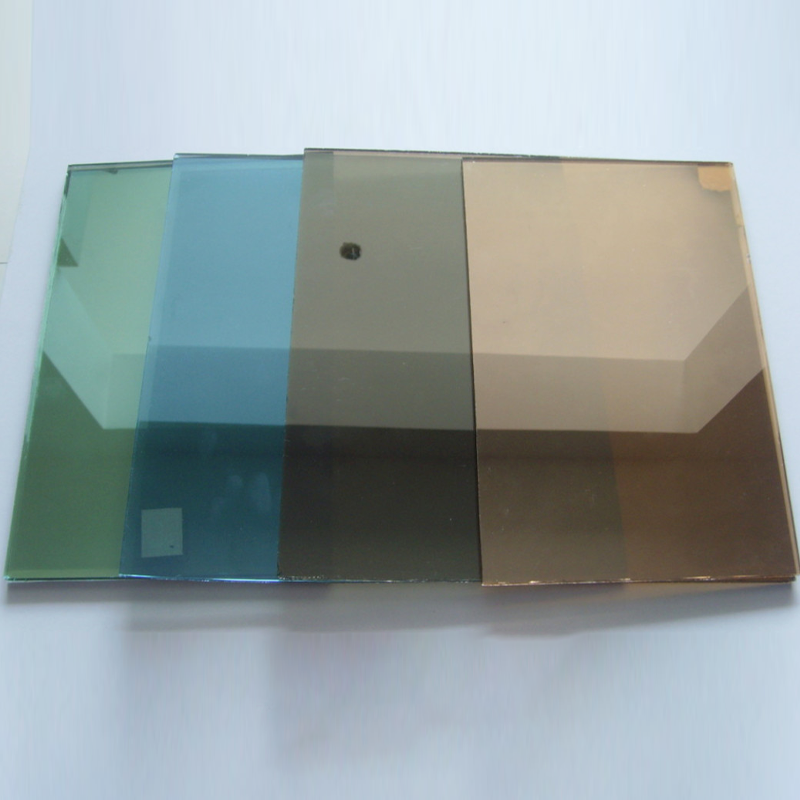

In various fields such as architecture, automotive, and electronics, coated glass occupies an indispensable and important position. Based on ordinary glass, it deposits one or more functional thin films on the surface of glass through specific production processes, thereby endowing glass with special properties such as heat insulation, thermal insulation, ultraviolet resistance, anti-glare, and conductivity, which greatly expands the application range of glass.

With the continuous improvement of market requirements for the performance of coated glass, its production methods are also continuously optimized and innovated. At present, there are four main mainstream production methods for coated glass in the industry, namely magnetron sputtering in vacuum, chemical vapor deposition (CVD), sol-gel method, and vacuum evaporation coating. Next, we will elaborate on these production methods in detail to deeply understand their technical principles, process characteristics, and application scenarios.

1. Magnetron Sputtering in Vacuum: Mainstream and Efficient Coating Technology

Magnetron sputtering in vacuum is currently the most widely used and technically mature production method for coated glass, especially dominating the fields of architectural coated glass and automotive glass coating. Its core principle is that in a vacuum environment, the movement of electrons is constrained by a magnetic field, causing electrons to collide with inert gases such as argon and ionize to generate plasma. Positive ions in the plasma bombard the target material (coating material) under the action of an electric field, causing atoms or molecules of the target material to sputter out and deposit on the surface of the glass substrate to form a uniform functional thin film.

This production method has many advantages:

- A wide range of coating materials can be selected, including metals, metal oxides, nitrides, etc., and coated glass with different functions can be prepared according to requirements, such as low-emissivity coated glass and solar control coated glass;

- The thin film has strong adhesion and good uniformity. The deposited thin film is closely combined with the glass substrate, not easy to fall off, and the thickness deviation of the thin film is small, which can ensure the stable overall performance of the coated glass;

- High production efficiency, can realize continuous production, suitable for large-scale industrial mass production.

However, magnetron sputtering in vacuum also has disadvantages such as large equipment investment and high energy consumption, and has strict requirements on the production environment and operation technology.

In practical applications, coated glass produced by magnetron sputtering in vacuum is widely used in exterior wall glass of high-rise buildings, front windshields and side windows of automobiles, etc. For example, low-emissivity coated glass deposits low-emissivity metal films such as silver through magnetron sputtering technology, which can effectively block the transmission of infrared rays, reduce heat exchange between indoor and outdoor, and achieve energy-saving and thermal insulation effects; solar control coated glass adjusts the transmittance of visible light by depositing specific metal or metal oxide films, reduces glare, and improves indoor comfort.

2. Chemical Vapor Deposition (CVD): Low-Cost On-Line Coating Technology

Chemical Vapor Deposition (CVD) is another important production method for coated glass. According to different production scenarios, it can be divided into on-line chemical vapor deposition and off-line chemical vapor deposition, among which on-line chemical vapor deposition is more widely used in the production of coated glass. Its technical principle is to place the glass substrate in a specific reaction atmosphere, and make the reaction gas undergo chemical decomposition, combination and other reactions through heating or plasma, and the reaction products are deposited on the surface of the glass to form a functional thin film.

The biggest feature of on-line chemical vapor deposition is that the coating process can be completed directly in the tin bath or annealing kiln of the float glass production line without additional vacuum equipment, which can be synchronized with the production process of glass, greatly shortening the production process and reducing production costs. At the same time, the coated glass produced by this method has good wear resistance and corrosion resistance, and the thin film has strong bonding force with the glass substrate, which can adapt to subsequent processing processes such as cutting and bending.

Its disadvantages are:

The selection of coating materials is relatively limited, mainly metal oxides;

The uniformity of the thin film and the difficulty of performance control are relatively large, and it is difficult to prepare high-precision functional thin films.

Due to its low cost and high production efficiency, coated glass produced by chemical vapor deposition is widely used in medium and low-end architectural glass, ordinary civil glass and other fields. For example, tin oxide conductive coated glass deposited on-line can be used to prepare transparent conductive glass, which is applied to electronic devices such as liquid crystal displays and solar cells; titanium dioxide self-cleaning coated glass is prepared by chemical vapor deposition, which has good hydrophilicity and photocatalytic performance, can automatically decompose surface pollutants, and keep the glass surface clean.

3. Sol-Gel Method: Flexible and Convenient Low-Temperature Coating Technology

The sol-gel method is a production method for coated glass based on solution chemical reactions. Its technical principle is to uniformly coat a solution containing coating material precursors (sol) on the surface of the glass substrate by dipping, spraying, spin coating and other methods, and then through low-temperature drying, calcination and other treatments, the sol undergoes condensation and polymerization reactions to form a gel, and finally converts into a dense functional thin film.

The advantages of this production method are very obvious:

Simple equipment and low investment, no need for vacuum environment and high-temperature reaction conditions, convenient operation, suitable for small-scale production or laboratory research and development;

Flexible coating process, which can accurately control the composition and thickness of the thin film by adjusting parameters such as the type, concentration and coating method of the precursor, and can prepare multi-component and multi-layer structured functional thin films;

Wide application range, can coat glass substrates of various shapes and sizes, including curved glass and special-shaped glass.

However, the sol-gel method also has disadvantages such as low production efficiency, low film density, and poor adhesion compared with magnetron sputtering, which makes it difficult to meet the needs of large-scale industrial production.

Coated glass produced by the sol-gel method is mainly used in the field of special functional glass, such as optical coated glass, antibacterial coated glass, anti-reflection coated glass, etc. For example, depositing thin films such as silicon dioxide and titanium dioxide on the surface of glass for optical instruments through the sol-gel method can prepare anti-reflection coated glass and improve the light transmittance of the glass; depositing silver ion thin films on the surface of medical glass can prepare antibacterial coated glass and reduce bacterial growth.

4. Vacuum Evaporation Coating: Traditional High-Precision Coating Technology

Vacuum evaporation coating is one of the earliest technologies applied in the production of coated glass. Its core principle is to heat the coating material to an evaporation state through resistance heating, electron beam heating and other methods in a high vacuum environment. The evaporated material atoms or molecules fly freely in the vacuum environment and finally deposit on the surface of the glass substrate to form a thin film.

Advantages of vacuum evaporation coating:

High purity and good surface finish of the thin film, which can prepare high-precision thin films, suitable for preparing coated glass with high optical performance requirements;

Fast coating speed, good coating effect on glass substrates with simple shapes.

Its obvious disadvantages:

Weak adhesion of the thin film, the bonding force with the glasssubstrate is not as good as that of magnetron sputtering, and it is easy to fall off;

Poor uniformity of the coating, it is difficult to prepare a uniform thin film on a large-area glass substrate;

Low utilization rate of coating materials and relatively high production costs.

At present, the application of vacuum evaporation coating in the production of coated glass is gradually decreasing, and it is mainly used in some special fields with extremely high requirements on the optical performance of thin films, such as the coating of high-precision optical glass such as optical lenses and laser lenses. In addition, vacuum evaporation coating still has a certain application space in the production of some miniaturized and customized coated glass.

5. Summary: Selection of Different Production Methods and Development Trends

Each of the above four production methods has its own advantages and disadvantages, and is suitable for different application scenarios and production needs:

Magnetron sputtering in vacuum: With excellent film performance and high production efficiency, it has become the mainstream choice for current industrial production of coated glass;

Chemical vapor deposition: With the advantages of low cost and on-line production, it occupies an important position in the production of medium and low-end coated glass;

Sol-gel method: Due to its flexibility and low threshold, it is suitable for the research and development and small-scale production of special functional coated glass;

Vacuum evaporation coating: Mainly used in special fields such as high-precision optical coated glass.

With the continuous progress of science and technology, the production methods of coated glass are also developing towards the direction of high efficiency, energy saving, environmental protection and multi-function. In the future, on the one hand, we will further optimize the existing production processes, reduce equipment investment and energy consumption, and improve film performance and production efficiency; on the other hand, we will actively develop new coating technologies, such as atomic layer deposition and plasma-enhanced chemical vapor deposition, to expand the functions and application fields of coated glass. At the same time, with the deepening of the concept of green and low carbon, environmentally friendly coating materials and energy-saving production processes will become the focus of the coated glassindustry, promoting the high-quality development of the coated glass industry.

In short, understanding the main production methods of coated glass helps us select suitable coated glass products according to actual needs, and also better grasp the technical development trend of the coated glass industry. Under the background of the continuous upgrading of the glass deep processing industry, as a high-value-added glass product, the production technology of coated glass will continue to innovate and break through, bringing more high-quality and efficient solutions to various fields.