How Much Do You Know About the Differences Between Vacuum Glass and Insulated Glass?

In modern architecture and home decoration, the choice of glass significantly impacts energy efficiency, sound insulation, and thermal insulation performance. Insulated glass and vacuum glass are two common high-performance glass products. While they may look similar in appearance, they differ significantly in structure, performance, and application. This article will explore the differences between these two types of glass in detail, helping readers better understand their advantages, disadvantages, and suitable scenarios.

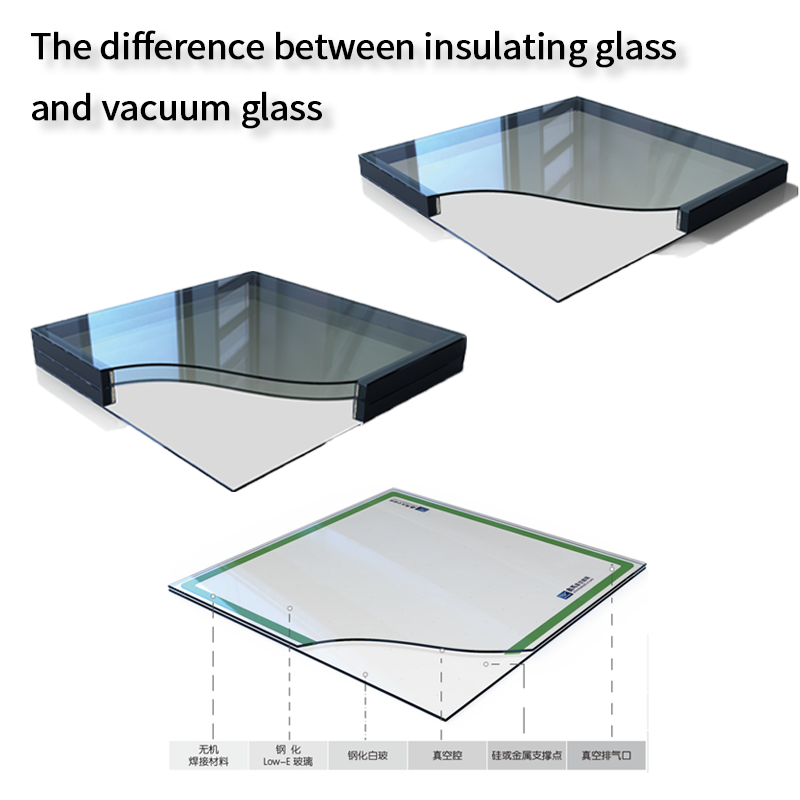

1. Differences in Structure and Manufacturing Process

(1) Structure of Insulated Glass

Insulated glass (Insulated Glass Unit, IGU) consists of two or more panes of glass separated by spacers (typically made of aluminum or warm-edge materials) and sealed around the edges with sealant (such as butyl and silicone). This creates a closed air gap or a layer of inert gas (e.g., argon or krypton). Its structure is usually represented as "glass + air gap + glass," for example, 5mm glass + 12mm air gap + 5mm glass (5+12A+5).

Manufacturing Process:

Glass cutting and cleaning;

Installing spacers and filling them with desiccant;

Assembling the panes and applying butyl sealant to the edges;

Secondary sealing (silicone or polysulfide sealant);

Filling with inert gas (optional).

(2) Structure of Vacuum Glass

Vacuum glass (Vacuum Insulated Glass, VIG) consists of two panes of glass with a vacuum layer (pressure below 0.1Pa) in between. Tiny support pillars (made of metal or ceramic) maintain a small gap (typically 0.1–0.2mm), and the edges are hermetically sealed using fusion sealing technology (e.g., low-melting-point glass or metal solder). Its structure can be represented as "glass + vacuum layer + glass," for example, 4mm glass + 0.1mm vacuum layer + 4mm glass (4+0.1V+4).

Manufacturing Process:

Glass cleaning and optional Low-E coating;

Placing micro-support pillars on the glass surface;

Assembling the panes and edge-sealing at high temperatures;

Evacuating the air and permanently sealing;

Testing the vacuum level.

2. Performance Comparison

(1) Thermal Insulation Performance

Insulated Glass: Relies on the low thermal conductivity of air or inert gas, with a U-value typically ranging from 1.4 to 2.8 W/(m²·K). Filling with argon can reduce this to 1.0–1.4 W/(m²·K).

Vacuum Glass: The vacuum layer almost completely blocks gas conduction and convection, achieving a U-value as low as 0.4–0.8 W/(m²·K), outperforming insulated glass in thermal insulation.

(2) Sound Insulation Performance

Insulated Glass: Effective against mid-to-high-frequency noise (e.g., human voices, traffic) but less effective against low-frequency noise (e.g., airplanes, trains).

Vacuum Glass: The vacuum layer effectively blocks sound transmission, especially low-frequency noise, providing superior overall sound insulation.

(3) Thickness and Weight

Insulated Glass: Due to the thicker air gap (typically 6–20mm), the overall thickness is greater, but the weight is relatively lighter.

Vacuum Glass: The vacuum layer is extremely thin (0.1–0.2mm), making the overall thickness smaller and suitable for space-constrained applications. However, the support pillars may add localized weight.

(4) Anti-Condensation Performance

Insulated Glass: In extreme temperature differences, the edges may condense due to higher thermal conductivity.

Vacuum Glass: The vacuum layer has almost no thermal conduction, reducing the risk of edge condensation.

(5) Lifespan

Insulated Glass: The sealant may degrade over time, leading to moisture ingress or inert gas leakage, with a typical lifespan of 15–20 years.

Vacuum Glass: Uses metal or glass fusion sealing for better airtightness, with a theoretical lifespan exceeding 25 years.

3. Application Scenarios

(1) Suitable Scenarios for Insulated Glass

Standard residential windows;

Commercial building facades;

Environments with moderate thermal insulation requirements;

Budget-constrained projects.

(2) Suitable Scenarios for Vacuum Glass

Ultra-low-energy buildings (e.g., passive houses);

Spaces requiring high sound insulation (e.g., near airports, noisy urban areas);

Extremely cold regions needing superior insulation;

Special applications (e.g., museums, laboratories).

4. Cost Comparison

Insulated Glass: Mature technology and lower cost, priced around 200–500 RMB/㎡.

Vacuum Glass: Complex manufacturing process and higher cost, priced around 800–2000 RMB/㎡.

5. Future Development Trends

Insulated Glass: Future improvements may focus on optimizing spacer materials (e.g., warm-edge technology) and gas-filling processes to enhance performance.

Vacuum Glass: As technology advances and production scales up, costs are expected to decrease, expanding its applications.

6. Summary

| Comparison | Insulated Glass | Vacuum Glass |

| Structure | Glass + air gap + glass | Glass + vacuum layer + glass |

| Thermal Insulation | Good (U-value 1.0–2.8) | Excellent (U-value 0.4–0.8) |

| Sound Insulation | Moderate | Superior |

| Thickness | Thicker | Ultra-thin |

| Cost | Lower | Higher |

| Applications | Standard buildings | High-end energy-efficient buildings |

Conclusion:

If budget is limited and thermal insulation requirements are moderate, insulated glass is a cost-effective choice.

If superior thermal insulation, soundproofing, and budget are not constraints, vacuum glass is the better option.

With the development of green buildings, vacuum glass may become mainstream in the future. However, insulated glass remains the dominant product in the current market. Consumers should choose the appropriate type based on their specific needs.

vacuum glass vacuum glass vacuum glass vacuum glass vacuum glass vacuum glass vacuum glass vacuum glass vacuum glass