Fused Art Glass: The Eternal Beauty of Molten Time

In the fields of contemporary architecture and interior design, fused glass is captivating visual senses with its unique artistic expressiveness and limitless possibilities. As an art form that perfectly integrates traditional craftsmanship with modern aesthetics, fused glass not only redefines the boundaries of glass applications but also opens up new dimensions for art glass creation. This article delves into the distinctive features, diverse types, and intricate manufacturing methods of fused glass, inviting you to appreciate the eternal beauty of this time-molten art.

The Unique Charm of Fused Glass: When Temperature Meets Creativity

The most remarkable characteristic of fused glass lies in its extraordinary plasticity. Ordinary glass softens and flows under high temperatures, and fused glass leverages this property by being shaped within a specific temperature range (typically between 600°C and 900°C). This process creates subtle undulations and three-dimensional effects on the glass surface, resulting in a unique texture and visual impact unattainable with ordinary flat glass.

The reason art glass often employs the fusing process stems from the unique aesthetic value it imparts. The surface of fused glass exhibits soft, flowing curves, and when light passes through, it produces fascinating refraction effects, creating a dreamlike play of light and shadow. Each piece of fused glass is one-of-a-kind; even works produced using the same technique will show subtle variations due to slight differences in temperature and glass composition, which is precisely where its artistic value lies.

Beyond its aesthetic qualities, fused glass also boasts excellent physical properties. The high-temperature treatment stabilizes the internal structure of the glass, enhancing its strength and heat resistance compared to ordinary glass. Additionally, the fusing process can produce glass of various thicknesses and textures, meeting different functional requirements and safety standards.

The Ever-Changing Family of Fused Glass: Types and Expressions

Depending on the production technique and final effect, fused glass can be categorized into several types, each with its unique visual expression and application scenarios.

Flat fused glass is the most common form. Through heat treatment on molds, flat glass is imbued with various textures and patterns. This type of art glass is widely used in interior partitions, door and window decorations, and furniture panels, adding an artistic touch to modern spaces while maintaining functionality.

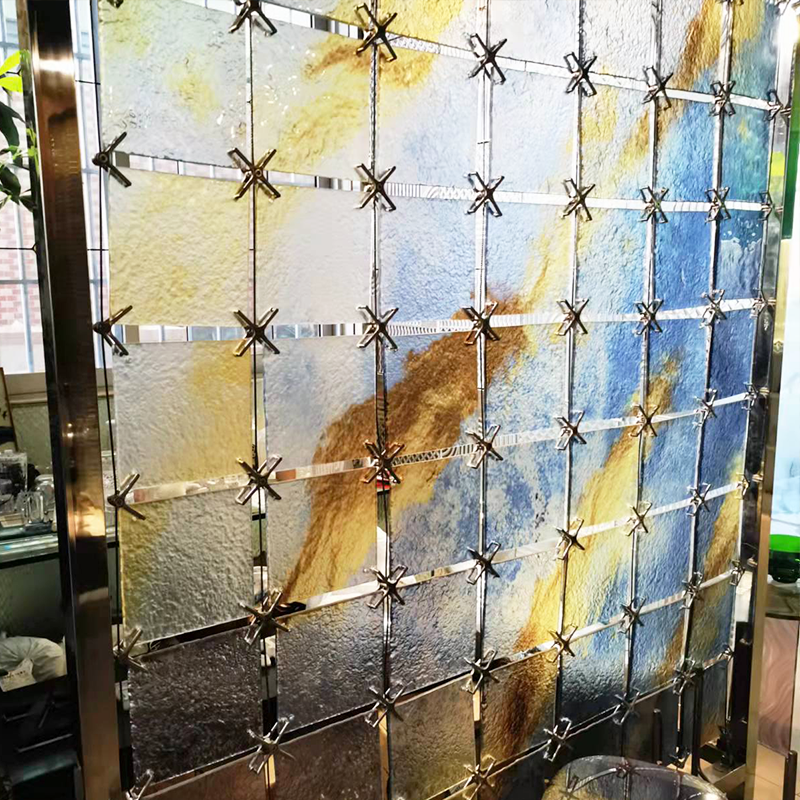

Three-dimensional fused glass takes it a step further. By precisely controlling temperature and time, glass is molded into three-dimensional forms. Such works are often found in high-end decorative fields, such as sculptural installations, artistic chandeliers, and feature accent walls, showcasing the ultimate expression of fused glass as art glass.

Composite fused glass combines multiple materials and techniques. Metal foils, mineral pigments, or other materials are often embedded between glass layers and fused together under heat to create richly layered and colorful effects. This type of fused glass significantly expands the creative boundaries of art glass, enabling artists to realize more complex conceptual designs.

Furthermore, based on surface effects, fused glass can be classified into full-fuse, half-fuse, and tack-fuse types. Full-fuse completely melts the glass surface, creating a smooth, water-like effect; half-fuse retains some texture; tack-fuse only slightly softens the glass surface, producing a subtle, hazy beauty.

From Sand to Artwork: The Manufacturing Secrets of Fused Glass

The creation of fused glass is a precise craft that blends science and art, requiring skilled technique and meticulous attention at every step.

The process begins with glass selection. Specially formulated art glass materials are typically used, with thermal expansion coefficients and melting properties designed to ensure stability during the heat treatment. Glass can be chosen in transparent, colored, or textured varieties, laying the foundation for the final effect.

The design phase is critical in fused glass creation. Artists must carefully plan the flow behavior of the glass under high temperatures, calculating shrinkage rates and morphological changes. Modern fused glass production often employs computer-aided design to simulate shape changes under heat, ensuring the finished product aligns with the creative vision.

Mold making is the core step determining the form of the artwork. Mold materials must withstand high temperatures without adhering to the glass, with common choices including refractory plaster, ceramic fiberboard, or stainless steel. The mold design directly influences the final shape and surface texture of the glass, representing a key technique in fused glass production.

The fusing process is the climax of the craft. Cut glass pieces are placed into the mold and loaded into a specialized kiln for heating. Temperature control is crucial, with heating curves strictly set according to the glass type and desired effect. The process typically consists of four stages: low-temperature preheating to relieve stress, medium-temperature heating to soften the glass, high-temperature shaping to fully conform the glass to the mold, and finally slow cooling for annealing to eliminate internal stress.

Annealing is an often overlooked but vital step in fused glass production. After high-temperature shaping, the glass contains significant internal stress, and without carefully controlled cooling, it is prone to cracking. The annealing process may take hours or even days, depending on the thickness and size of the glass.

Post-processing adds the finishing touches to fused glass artworks. Cooled pieces may require edge polishing, surface cleaning, or assembly with other materials to become complete art glass works.

Applications of Fused Glass: Infinite Possibilities Blending Art and Life

Thanks to its unique charm, fused glass has found extensive applications in architecture and interior design. In commercial spaces, fused glass partitions and decorative walls create distinctive brand identities; in residential environments, art glass doors, windows, and screens infuse living spaces with artistic flair; in the realm of public art, large-scale fused glass installations become highlights of urban landscapes.

It is worth noting that fused glass is increasingly integrating with modern technology, opening up new application areas. Embedding LED lighting within or behind fused glass creates dynamic light and shadow effects; combining with smart dimming technology allows flexible transitions between privacy and transparency; and even integrating with solar technology leads to the development of aesthetically pleasing and energy-efficient building façade materials.

Conclusion: An Art Form in Eternal Flow

As an important branch of artistic glass, fused glass embodies humanity's relentless pursuit of material mastery and artistic expression. It retains the transparent and dynamic nature of glass while infusing solid materials with a sense of flowing rhythm through the fusing process. From its characteristics to its types, from manufacturing methods to application fields, fused glass demonstrates infinite possibilities and timeless charm.

With technological advancements and evolving aesthetics, fused glass will continue to innovate and develop, finding a more perfect balance between art and function, and bringing more beauty and inspiration to human spaces. Each fusing process is a miracle of material transformation and artistic creation, which is the eternal allure of fused glass as a premier form of artistic glass.

art glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glass