Detailed Explanation of Glass Specifications and Common Sizes of Fireproof Glass

Introduction

Glass, as a common building material, is widely used in construction, home furnishings, decoration, and other fields. With advancements in technology, the types and functions of glass have become increasingly diverse. Among them, fireproof glass and insulated glass play vital roles in the construction industry due to their unique properties. This article provides a detailed introduction to the common specifications and sizes of glass, with a focus on the standard dimensions and applications of fireproof glass and insulated glass.

I. Common Specifications and Sizes of Glass

The specifications and sizes of glass vary depending on its intended use. Common types include flat glass, tempered glass, laminated glass, and more. Below are the size ranges for several common types of glass:

1. Flat Glass

Flat glass is the most basic type of glass, primarily used for windows, doors, and curtain walls. Its standard dimensions typically include:

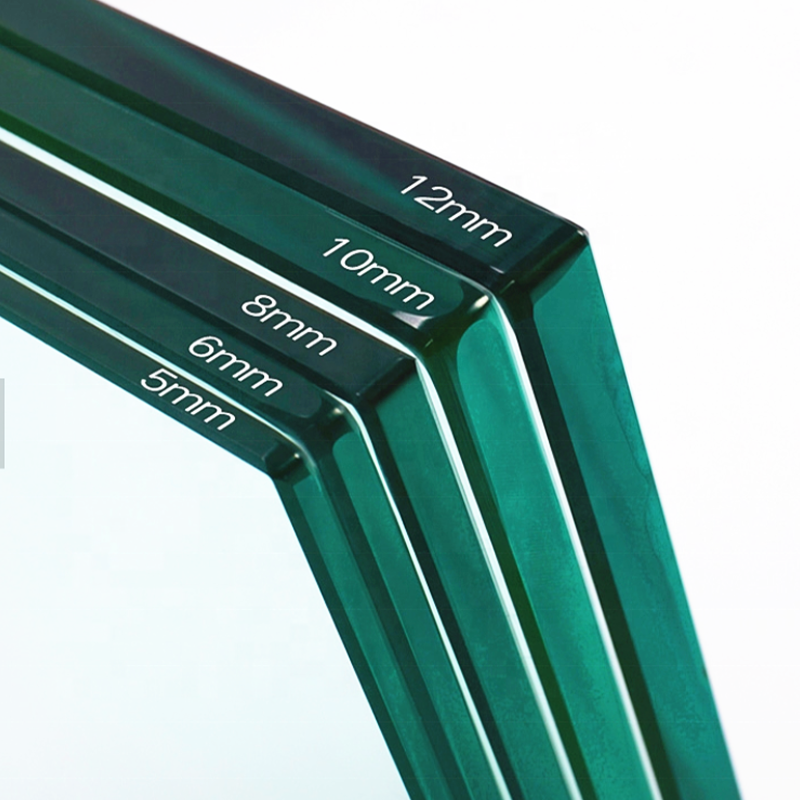

Thickness: 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, etc.

Width: Usually 1200mm to 3300mm.

Length: Usually 1500mm to 6000mm.

Larger sizes may be used for building curtain walls, but transportation and installation become more challenging.

2. Tempered Glass

Tempered glass offers high strength and impact resistance, making it widely used in construction and furniture industries. Common sizes include:

Thickness: 4mm to 19mm.

Maximum size: Generally does not exceed 2400mm × 4200mm (limited by tempering furnaces).

3. Laminated Glass

Laminated glass consists of two or more layers of glass bonded with PVB or EVA film, making it suitable for high-security applications. Common dimensions include:

Thickness: 6mm to 50mm (depending on the number of layers).

Maximum size: Typically does not exceed 2400mm × 4200mm.

4. Insulated Glass

Insulated glass is composed of two or more panes of glass separated by a sealed air or inert gas space, providing excellent sound and thermal insulation. Common sizes include:

Thickness: 12mm to 60mm (including the air gap).

Standard sizes: 1000mm × 2000mm, 1500mm × 3000mm, etc.

Maximum size: Generally does not exceed 2500mm × 4500mm.

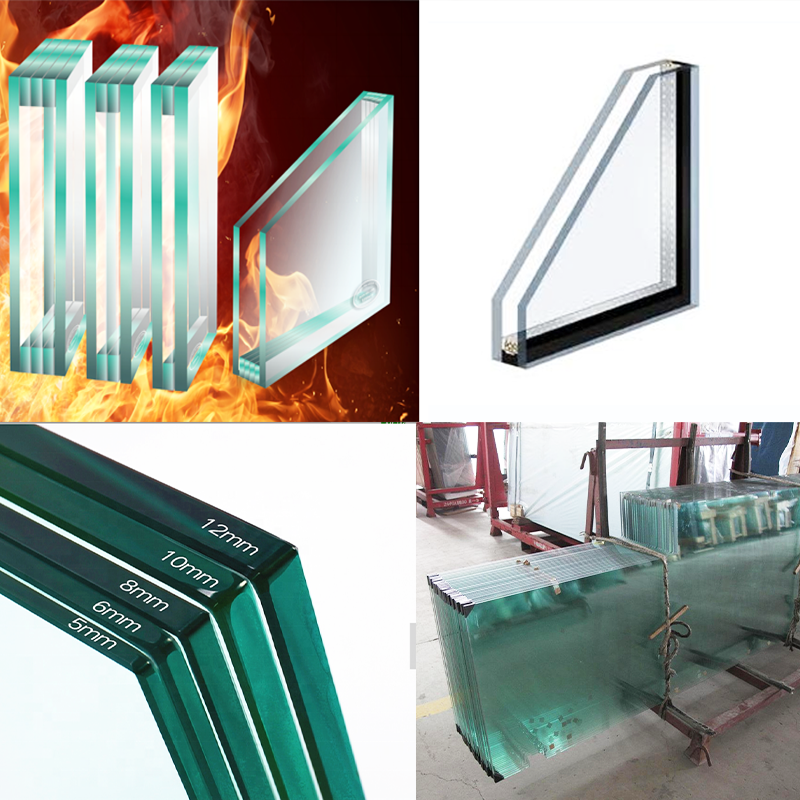

II. Common Sizes of Fireproof Glass

Fireproof glass is a specialized type of glass that can block flames and smoke during a fire, providing critical time for evacuation. Its dimensions vary depending on fire resistance ratings.

1. Classification of Fireproof Glass

Fireproof glass can be categorized by fire resistance:

Class A (Insulated Fireproof Glass): Meets both integrity and insulation requirements, such as laminated composite fireproof glass.

Class B (Partially Insulated Fireproof Glass): Offers some insulation but less than Class A.

Class C (Non-Insulated Fireproof Glass): Only meets integrity requirements, such as monolithic cesium-potassium fireproof glass.

2. Common Sizes of Fireproof Glass

The dimensions of fireproof glass are more strictly regulated due to production and installation requirements. Below are standard sizes for common types:

(1) Monolithic Cesium-Potassium Fireproof Glass (Class C)

Thickness: 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm, etc.

Common sizes: 1200mm × 2400mm, 1500mm × 3000mm, etc.

Maximum size: Generally does not exceed 2000mm × 4000mm.

(2) Composite Fireproof Glass (Class A)

Thickness: 15mm to 50mm (depending on fire resistance rating).

Common sizes: 1000mm × 2000mm, 1200mm × 2400mm, etc.

Maximum size: Typically does not exceed 1800mm × 3600mm (limited by lamination processes).

(3) Fireproof Insulated Glass

Thickness: 20mm to 60mm (including the air gap).

Common sizes: 1000mm × 2000mm, 1500mm × 3000mm, etc.

3. Relationship Between Fire Resistance and Size

The fire resistance rating (e.g., 30 minutes, 60 minutes, 90 minutes, 120 minutes) of fireproof glass is closely related to its thickness and structure. Generally:

30-minute fireproof glass: Typically 5mm to 12mm thick.

60-minute fireproof glass: Usually 15mm to 25mm thick.

90-minute and above fireproof glass: Often uses multi-layer composite structures, with thicknesses exceeding 30mm.

III. Features and Applications of Insulated Glass

Due to its unique structure, insulated glass plays a crucial role in energy-efficient buildings. Key features include:

1. Excellent Thermal Insulation

The air gap in insulated glass significantly reduces heat transfer, making it ideal for cold climates and energy-saving buildings.

2. Superior Soundproofing

A 6mm+12A+6mm insulated glass configuration can reduce noise by over 30 decibels, suitable for buildings near busy streets.

3. Anti-Condensation Properties

The air layer prevents condensation on the interior surface of the glass.

4. Common Applications

Residential and office building windows

Curtain wall systems

Skylights for sunrooms

Environments requiring stable temperature and humidity (e.g., museums, laboratories)

IV. Comparison of Fireproof Glass and Insulated Glass Applications

| Feature | Fireproof Glass | Insulated Glass |

|---|---|---|

| Primary Function | Fire resistance | Thermal and sound insulation |

| Typical Use | Fire exits, server rooms, high-rise building cores | Homes, offices, hotels |

| Standard Thickness | 5mm to 50mm | 12mm to 60mm |

| Special Requirements | Must pass fire safety certifications | Requires airtight sealing |

V. Key Considerations When Purchasing Glass

Select Based on Application: Standard windows may use tempered or insulated glass, while fire-prone areas require fireproof glass.

Check Performance Metrics: Fireproof glass should specify fire resistance ratings, while insulated glass should list U-values (thermal transmittance).

Ensure Proper Sizing: Glass dimensions must match frames, especially accounting for thermal expansion in insulated glass.

Verify Certifications: Fireproof glass must comply with GB 15763.1 standards, while insulated glass should meet GB/T 11944 requirements.

VI. Future Trends

As building safety standards rise, demand for fireproof glass and insulated glass will continue growing. Future developments may include:

Multi-functional Composites: Combining fireproof and insulating properties in fireproof insulated glass.

Lightweight Designs: Reducing weight without compromising performance.

Smart Integration: Embedding temperature sensors in fireproof glass for automatic alarms.

Conclusion

Glass is an indispensable material in modern construction, with diverse specifications and applications. Fireproof glass ensures building safety with its flame-resistant properties, while insulated glass enhances comfort through thermal and acoustic insulation. Understanding the specifications and characteristics of different types of glass enables informed decisions to meet specific needs, ensuring safety, functionality, and aesthetics. As technology advances, glass products will evolve toward higher performance and smarter solutions.