Concerns in Laminated Glass: An In-depth Analysis of Interlayer Wrinkles and Visual Defects

In contemporary architecture and the automotive industry, the application of glass has long transcended its basic functions of lighting and weather protection, now bearing significant responsibilities for safety, aesthetics, and design. Among these applications, laminated glassstands out as a composite material that has become the preferred choice for curtain walls, skylights, railings, and automotive windshields due to its exceptional safety, sound insulation, and UV protection properties. However, even such a mature product is not without flaws. Some users occasionally notice subtle wrinkles, waves, or visual imperfections such as bubbles and impurities within the laminated glass. Where do these defects originate? Do they impact the core performance of laminated glass? This article provides a comprehensive analysis.

I. What is Laminated Glass? – The Foundation of Superior Performance

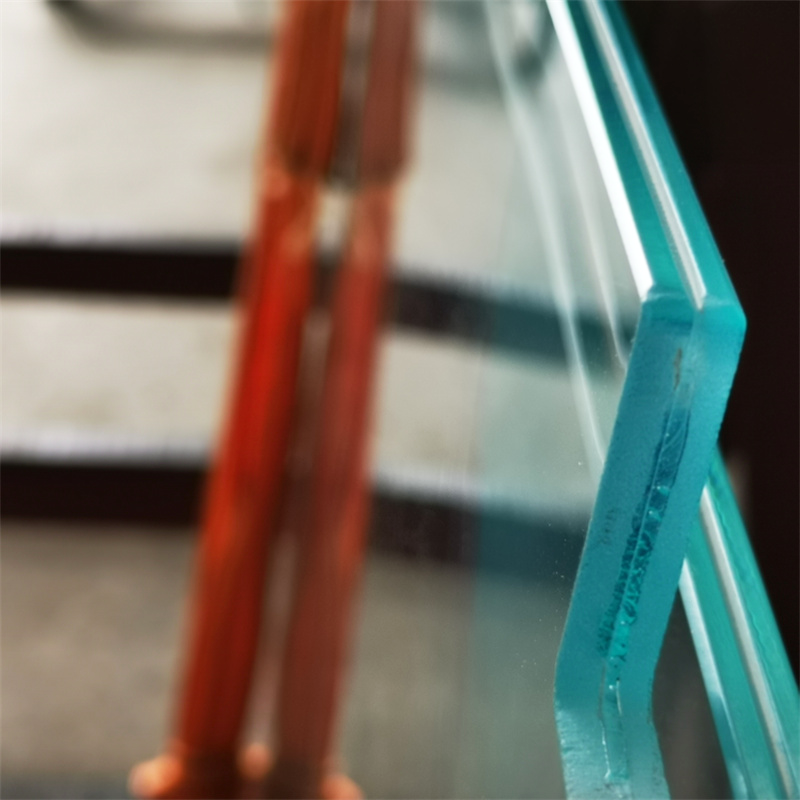

Before delving into its drawbacks, it is essential to understand the composition of laminated glass. As the name suggests, laminated glass is a composite product made by permanently bonding two or more sheets of glass with one or more layers of a resilient polymer interlayer (most commonly PVB film) through a high-temperature, high-pressure process.

This transparent interlayer is the soul of laminated glass. It endows laminated glass with a range of advantages that traditional monolithic glass cannot match:

Safety: When the glass is impacted and shatters, the fragments adhere firmly to the interlayer, preventing them from scattering and causing injury, thereby creating a "safety film" effect.

Sound Insulation: The PVB interlayer acts as a damping material, effectively absorbing and reducing sound wave vibrations, thereby enhancing acoustic performance.

UV Protection: It blocks over 99% of ultraviolet radiation, protecting indoor furniture and fabrics from fading.

Structural Integrity: Even when broken, it maintains a certain degree of integrity, providing a temporary barrier.

It is these advantages that make laminated glass highly sought after in the market. However, the very component that gives it these properties—the interlayer—is also the primary source of visual defects.

II. The Core Issue: Why Do Wrinkles and Visual Defects Appear in the Interlayer?

The interlayer in laminated glass should ideally remain "invisible" and undetectable to the naked eye. However, when deviations occur in the production process or raw materials, it becomes noticeable, primarily manifesting as wrinkles and other visual imperfections.

1. Interlayer Wrinkles (Waves/Water Marks)

This is the most common type of visual defect, appearing as water-like waves or fine wrinkles when the laminated glass is viewed from the side or at an angle under specific lighting conditions.

In-depth Analysis of Causes:

Characteristics of the Interlayer Itself: PVB film is a polymer material with certain hygroscopic and thermoplastic properties. If environmental humidity is not properly controlled during storage, the edges of the film can absorb moisture from the air. During subsequent lamination and pre-press exhaust processes, areas with varying moisture content shrink at different rates when heated, resulting in fine, irremovable wrinkles.

Challenges in the Lamination Process: The process of spreading the interlayer between two sheets of glass is called "lamination." If the film is unevenly tensioned during spreading or has inherent quality issues (such as thickness variations), the seeds of wrinkles are sown at the initial bonding stage.

Limitations of the Autoclave Process: The key step in forming laminated glass is the autoclave process, where high temperature and pressure cause the interlayer to fully melt, release air, and bond firmly with the glass. If the heating rate is too rapid, pressure distribution is uneven, or air exhaust is incomplete, the interlayer may form fixed wrinkles during flow and curing. This is particularly challenging for large-format laminated glass, where ensuring absolute pressure uniformity across the entire surface is extremely difficult.

Quality of the Base Glass: This point is often overlooked. If the base glass itself exhibits optical distortions, commonly referred to as "waves," these distortions will combine with the interlayer wrinkling effect after lamination, making the visual issue more pronounced.

2. Other Common Visual Defects

Besides wrinkles, laminated glass may also exhibit the following issues:

Bubbles: This is one of the most troublesome defects. The primary causes include insufficient cleanliness during lamination, introducing dust or air, or inadequate pre-press exhaust, leaving residual bubbles that fail to fully dissolve into the interlayer during the autoclave process. A small number of minor bubbles may not affect safety performance but significantly impair aesthetics.

Impurities/Stains: If the interlayer or glass surfaces are not adequately cleaned during production, contaminants such as dust, fibers, or fingerprints can become permanently encapsulated within the laminated glass.

Discoloration of the Interlayer: Low-quality PVB film or the use of inappropriate cleaning agents may cause the interlayer to yellow over time, affecting the transparency and appearance of the laminated glass.

Edge Delamination: If edge sealing is poorly executed or the glass is exposed to harsh environments (e.g., prolonged water immersion), moisture may penetrate the edges of the laminated glass, causing local separation of the interlayer from the glass and loss of adhesion.

III. Do These Defects Affect the Safety Performance of Laminated Glass?

This is the most pressing concern for consumers. The answer must be considered on a case-by-case basis:

Slight, Uniform Wrinkles: Typically, minor and uniformly distributed interlayer wrinkles are classified as visual or optical defects rather than structural flaws. They generally do not significantly impact the core safety performance of laminated glass. When the glassshatters, the fragments remain adhered, and its anti-shatter and penetration resistance capabilities are largely unaffected. However, they severely compromise visual clarity and aesthetics, which is unacceptable, particularly in architectural curtain walls or high-end home designs that demand pristine views.

Severe Wrinkles, Bubbles, Delamination: If wrinkles are very severe and dense, or if there are numerous or large bubbles, or if edge delamination occurs, it indicates major flaws in the manufacturing process of the laminated glass. This may lead to stress concentration, reduce the overall strength of the glass, and compromise the reliability of fragment adhesion upon impact, thereby potentially undermining its safety performance. Such products should be deemed non-conforming.

IV. How to Avoid and Select: Advice for Consumers

Understanding the causes enables targeted measures to avoid purchasing problematic laminated glass:

Choose Reputable Brands and Suppliers: Established brands typically possess more advanced, stable production lines and stricter quality control systems, reducing the output of defective products from the source.

Focus on the Quality of the Base Glass: High-quality laminated glass starts with high-quality base glass. When selecting, inspect the base glass separately to ensure its optical distortions are within an acceptable range.

Conduct Careful Inspection Under Specific Lighting: Before installation or acceptance, do not only view the laminated glass head-on. Position it at an angle and examine it under various lighting conditions, such as sidelight and backlight, to more easily detect wrinkles and internal impurities.

Understand Relevant Standards: Various countries have national standards for the quality of laminated glass (e.g., China's GB 15763.3-2009). These standards permit certain defects that do not affect safety. Consumers can familiarize themselves with these standards as a basis for acceptance.

Ensure Proper Installation and Maintenance: Guarantee that the installation frame is level to avoid long-term stress distortion of the laminated glass. Use soft cloths and neutral cleaners for maintenance, and avoid prolonged contact of edges with corrosive substances.

Conclusion

Laminated glass is undoubtedly a significant invention that has greatly expanded the applications of glass, bringing enhanced safety and tranquility to our lives. Interlayer wrinkles and other visual defects are objective manifestations of the interplay between manufacturing precision and material properties. As consumers, we need not avoid this material altogether and dismiss the immense value of laminated glass. On the contrary, by scientifically understanding the causes and impacts of these imperfections, we can become more informed buyers, knowing how to identify and what to demand. This enables us to ultimately acquire laminated glass products that are both safe and reliable, as well as crystal clear, allowing this transparent guardian, built from glass and interlayer, to perfectly integrate into our spaces and lives.