Little Knowledge and Craftsmanship of Enameled Glass

Ⅰ. History and Development of Enameled Glass

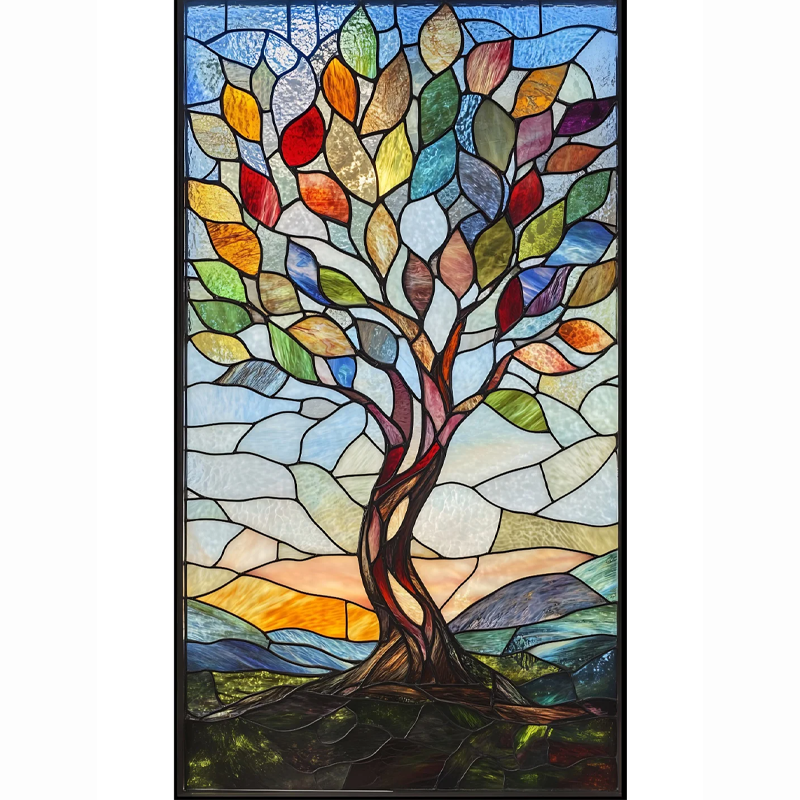

Enameled glass, as an ancient yet modern architectural decorative material, dates back to ancient Egypt and Babylon. Early enameled glass was mainly used in stained glass windows of churches, creating sacred and magnificent religious images with glazes of different colors. With technological advances, enameled glass gradually moved from religious buildings to civil and public architecture, becoming an indispensable element in architectural design.

Modern enameled glassnot only inherits traditional aesthetic value but also achieves breakthroughs in materials science and process technology. Today’s enameled glass not only serves decorative purposes but also possesses multiple functions such as energy efficiency, privacy protection, and safety. It is widely used in building curtain walls, interior partitions, furniture decoration, and more. Art glass, as an important branch of enameled glass, emphasizes individuality and artistic expression even more, becoming a highlight in modern space design.

Ⅱ. Basic Concepts and Characteristics of Enameled Glass

1. What is Enameled Glass?

Enameled glassis a type of decorative glass formed by applying one or more layers of inorganic glaze onto the surface of flat glass through a special process. After high-temperature sintering, the glaze permanently fuses with the glass surface. This process not only gives the glass rich colors and patterns but also retains the transparency of the glass itself.

2. Main Characteristics of Enameled Glass

Strong decorative appeal: Can be made into various colors, patterns, and textures to meet diverse design needs.

Excellent durability: The glaze fuses with the glass at high temperatures, offering strong weather resistance without fading or peeling.

Diverse functionality: Can achieve different light transmittance, reflectance, and thermal insulation properties by adjusting the glaze formula.

Eco-friendly and safe: Uses inorganic glazes, releases no harmful substances, and complies with green building standards.

Ⅲ. Craftsmanship and Production Process of Enameled Glass

1. Design and Pattern Creation

The production of enameled glass begins with the design phase. Designers create suitable patterns and color schemes based on architectural style and spatial requirements. This stage pays special attention to combining patterns with the characteristics of glass, fully considering the visual effects created by light passing through the glass. For art glass, this process places greater emphasis on artistic expression and uniqueness.

2. Glass Substrate Selection and Treatment

Selecting a suitable glass substrate is the foundation for producing high-quality enameled glass. Float glass, tempered glass, or laminated glass are commonly used as base materials. The glass surface must be thoroughly cleaned to remove oil stains and impurities, ensuring good adhesion of the glaze.

3. Glaze Preparation and Formulation

Glaze is the soul of enameled glass, mainly composed of inorganic pigments, glass powder, and binders. According to design requirements, technicians precisely formulate the proportions and colors of the glaze to ensure color consistency and stability. Modern enameled glass processes can also achieve special visual effects such as metallic textures and pearl luster.

4. Glaze Application Process

Glaze application is the core of enameled glass production. The main methods include:

(1) Screen Printing Method

This is the most commonly used glaze application process, suitable for mass production and complex patterns. The glaze is precisely printed onto the glass surface through a specially made screen, achieving fine pattern details and uniform glaze thickness. This method is widely used in the production of architectural curtain wall glass.

(2) Spray Glazing Method

A professional spray gun is used to atomize the glaze and evenly spray it onto the glass surface. This method is suitable for gradient colors and large-area monochromatic glass. Art glass produced this way often has unique layering and artistic expression.

(3) Hand-Painting Method

The traditional hand-painting process is mainly used for high-end custom art glass. Artists directly paint patterns on the glass surface, making each piece a unique work of art. This process preserves the most primitive artistic charm of enameled glass.

(4) Digital Printing Technology

The emerging digital printing technology has revolutionized the production of enameled glass. This technology allows high-precision direct printing of design patterns onto the glass surface without the need for plate-making, making it suitable for small-batch customization and complex image reproduction.

5. Drying and Sintering

After glaze application, the glass undergoes a drying process to remove moisture and volatiles from the glaze. It then enters a high-temperature sintering furnace. The sintering temperature typically ranges from 600°C to 700°C, melting the glaze and forming a chemical bond with the glass surface. This process determines the final quality and durability of the enameled glass.

6. Post-Processing and Treatment

After sintering, enameled glass can undergo further processing such as tempering, laminating, or insulating to enhance its safety and functionality. For special art glass, additional artistic processing like engraving or embedding may be performed.

Ⅳ. Application Areas of Enameled Glass

1. Building Facades and Curtain Walls

Modern architecture widely uses enameled glass as a curtain wall material, creating unique building appearances while regulating indoor light and temperature. Enameled glass with different patterns and densities can meet the lighting and privacy requirements of various parts of a building.

2. Interior Partitions and Decoration

Enameled glass also shines in interior design. As a space partition, it can divide functional areas while maintaining visual transparency; as a decorative wall, it adds an artistic atmosphere to the space. Art glass partitions are particularly highlights in high-end commercial and residential spaces.

3. Furniture and Household Items

From glass tabletops to cabinet door panels, enameled glass offers rich possibilities for furniture design. Customized art glass furniture has become a carrier for expressing individuality and taste.

4. Public Art Installations

Many contemporary artists choose enameled glass as a creative medium for large-scale public art installations. These works fully utilize the light-transmitting properties of glass and the expressive power of glazes, presenting ever-changing artistic effects under different lighting conditions.

Ⅴ. Innovation Trends in Enameled Glass

1. Smart Enameled Glass

Combining electrochromic and thermochromic technologies with enameled glass to develop smart glass products that automatically adjust light transmittance and color based on environmental conditions.

2. Development of Eco-Friendly Glazes

With increasing environmental awareness, the development of low-energy, heavy-metal-free eco-friendly glazes has become an important industry direction. Technologies such as water-based glazes and UV-curable glazes are changing the traditional production methods of enameled glass.

3. Integration of Composite Functions

Modern enameled glass is moving toward multifunctional integration, combining features such as photovoltaic power generation, self-cleaning, and antibacterial properties with decorative functions to create glass products with higher added value.

4. Digitalization and Customization

Digital printing technology and parametric design make the customization of enameled glass more convenient and economical. Customers can participate in the design process to create art glass works that fully meet their personal needs.

Ⅵ. Maintenance and Care of Enameled Glass

High-quality enameled glass has excellent durability, and daily maintenance is relatively simple:

Regularly clean the surface with mild cleaners and soft cloths.

Avoid using abrasive cleaning tools to prevent scratching the glazed surface.

For enameled glass used outdoors, professional inspection and maintenance are recommended annually.

Promptly clean stubborn stains attached to the surface to prevent long-term accumulation from affecting aesthetics.

Conclusion

Enameled glass, as a material that connects traditional craftsmanship with modern technology, continues to thrive in the fields of architecture and design. From the stained glass windows of ancient churches to the smart curtain walls of modern skyscrapers, enameled glass has continuously evolved to meet humanity’s relentless pursuit of beauty and functionality. Art glass, as its most expressive form, builds a bridge between art and craftsmanship. With technological advancements and innovative design concepts, we have reason to believe that enameled glass, this ancient material, will shine even more brilliantly in the future, continuing to enrich our architectural environments and living spaces.

Whether architects, designers, or ordinary users, understanding the knowledge and craftsmanship of enameled glass can help us better appreciate and apply this unique material, creating beautiful and practical glass artworks and architectural solutions. In the interplay of light and color, enameled glass will continue to write the infinite possibilities of transparent materials.

art glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glassart glass