A Deep Dive into Glass Printing Processes: The Unique Charms of Screen Printing and UV Printing

In modern industrial production and decoration fields, glass printing technology has been widely applied in scenarios such as architectural curtain walls, home decoration, electronic device panels, and automotive glass, thanks to its ability to endow glass products with personalized appearances and functional properties. Among them, screen-printed glass and UV-printed glass are two mainstream processes, which differ significantly in technical principles and application performance. A thorough understanding of these differences can provide key references for production and customization needs.

1. Overview of Glass Printing Technology

Glass printing technology is a processing method that transfers inks or other functional materials onto the glass surface through specific technical means to form patterns, text, or coatings. This technology not only enhances the aesthetics of glass products but also endows them with special functions such as sun protection, anti-glare, and electrical conductivity. Currently, in the field of glass printing, screen-printed glass and UV-printed glass occupy important market shares due to their unique process characteristics, meeting production and customization needs in different scenarios respectively.

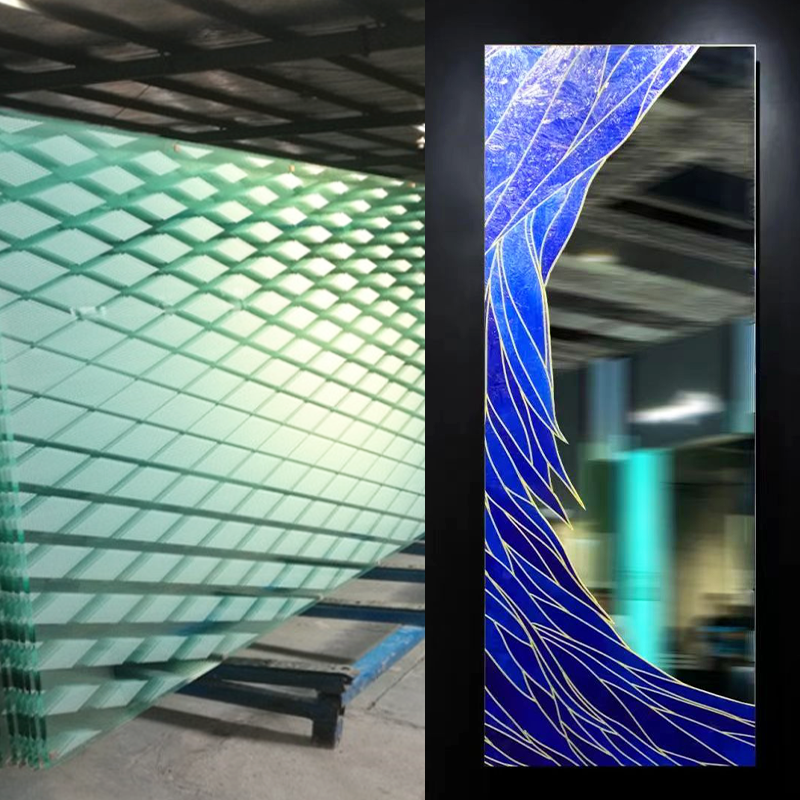

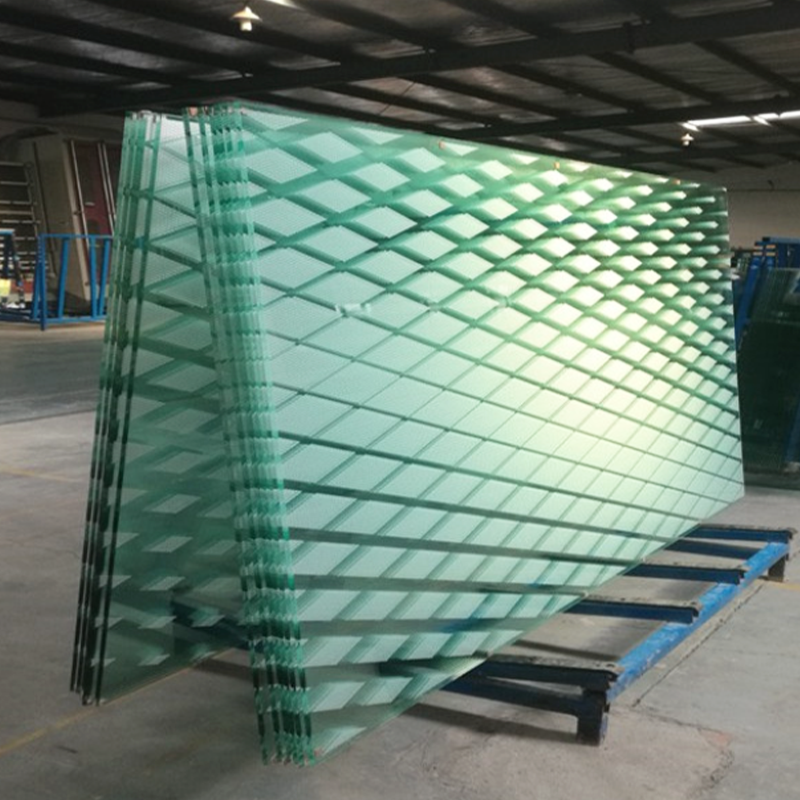

2. Characteristics of Screen Printing Process (Corresponding to Screen-Printed Glass)

2.1 Principle Analysis

The core principle of the screen printing process is to use a screen as a carrier and create a stencil with hollowed-out areas corresponding to the desired pattern on the screen (the screen holes in non-pattern areas are blocked, while those in pattern areas are hollowed out). During printing, the screen stencil is covered on the glass surface, then ink is poured onto the screen stencil, and a certain pressure is applied through a squeegee to make the ink pass through the hollowed-out areas of the screen and transfer to the glass surface, finally forming a clear pattern. The entire process relies on a "stencil printing" mechanism, and the combination of ink and the glass surface requires subsequent curing treatments (such as high-temperature baking or adding curing agents) to enhance adhesion.

2.2 Application Scope

In terms of materials, screen printing has strong applicability. In addition to glass, it can also be used for ceramics, metals, plastics, fabrics, and other materials. In terms of glass shapes, it can not only print on flat glass but also adapt to curved and special-shaped glass (such as curved automotive glass and cylindrical glassware), with high compatibility for glass shapes. In application scenarios, screen-printed glass is commonly used for pattern printing on architectural glass curtain walls, logo printing on home appliance glass panels, and decorative pattern printing on glassware.

2.3 Color Performance

Screen printing has certain limitations in color performance: Firstly, only one color can be printed at a time. To create multi-color patterns, multiple overprinting operations are required, and a new screen stencil corresponding to each color needs to be made for each overprint, resulting in a cumbersome process. Secondly, it is difficult to present gradient colors. Due to the single color of each printing, gradient effects need to be achieved by superimposing inks of the same color system with different concentrations multiple times. This not only involves complex operations but also tends to cause unnatural color transitions and blurred edges, making it difficult to meet the requirements of high-precision gradient patterns.

2.4 Color Adhesion

Screen-printed glass exhibits excellent color adhesion, which benefits from subsequent reinforcement treatments: After printing, curing agents are usually added to the ink, or the glass undergoes high-temperature tempering. Curing agents can promote a chemical reaction between the ink and the glass surface to form a firm bonding layer; tempering not only improves the strength of the glass but also further enhances the adhesion stability of the ink. After these treatments, the patterns on screen-printed glass are less likely to peel off or be scratched, and can withstand daily friction and a certain degree of acid-base corrosion, with strong durability, making it suitable for long-term outdoor or high-frequency use scenarios.

2.5 Cost Analysis

The cost structure of screen printing is characterized by "high initial cost and low subsequent cost": In the early stage, it is necessary to make a screen stencil according to the pattern. The stencil-making process involves multiple steps such as drawing, plate burning, and developing. Especially for screen stencils with complex patterns, the production cycle is long and the cost is high. However, in mass production, its advantages gradually emerge—once the screen stencil is made, the subsequent printing process is simple, the ink consumption is stable, and the printing cost per unit product decreases significantly. Therefore, screen-printed glass is more suitable for mass and standardized production needs, and the larger the batch, the lower the unit cost.

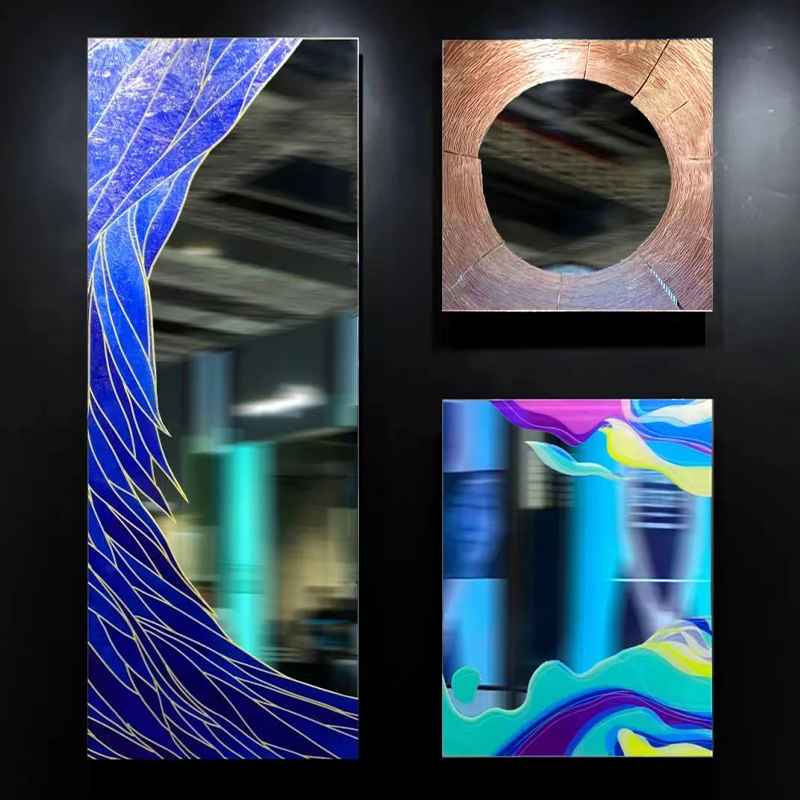

3. Characteristics of UV Printing Process (Corresponding to UV-Printed Glass)

3.1 Principle Analysis

The UV printing process features "ultraviolet curing" as its core technical highlight, using special UV inks (without volatile solvents). During printing, UV ink is directly sprayed onto the glass surface through the nozzles of the printing equipment to form a preliminary pattern; subsequently, the UV lamp built into the equipment immediately irradiates the ink on the glass surface. Under the action of ultraviolet light, the photosensitizer in the UV ink rapidly triggers a chemical reaction, and the ink cures in a very short time (usually a few seconds), changing from a liquid state to a solid state, and finally forming a stable pattern on the glass surface. The entire process does not require subsequent long-term baking, achieving "instant printing and instant drying".

3.2 Application Scope

UV printing has high requirements for the "non-absorbent" nature of materials, so it is more suitable for non-absorbent materials such as glass, metallic cardboard, plastics, and acrylics. In terms of glass shapes, current mainstream UV printing equipment is more suitable for flat glass. For curved or special-shaped glass, custom-made equipment is required, and its adaptability is relatively weaker than that of screen-printed glass. In application scenarios, UV-printed glass is often used for personalized customized products (such as custom glass photo frames and glass decorative paintings), small-batch electronic device glass panels, and short-term promotional glass displays, which can quickly respond to small-batch and diversified needs.

3.3 Color Performance

UV printing has significant advantages in color performance: Firstly, it supports "one-time multi-color printing". Through multi-color nozzles (such as CMYK four-color nozzles) of the equipment, rich multi-color patterns can be directly printed on the glass surface without multiple overprinting, resulting in a simple and efficient process. Secondly, it has an excellent performance in presenting gradient colors. The spray volume of UV ink can be precisely controlled by the equipment, enabling natural transitions from light to dark colors and from one color to another. The patterns have clear details and bright colors, which can meet the requirements of high-precision and high-aesthetic printing, especially suitable for printing complex artistic patterns.

3.4 Color Adhesion

Compared with screen-printed glass, the color adhesion of UV-printed glass is relatively weaker: Although UV ink can bond with the glass surface after UV curing, it is usually necessary to pre-spray a primer layer similar to a curing agent on the glass surface to improve adhesion. Even so, in scenarios of long-term outdoor use, frequent friction, or contact with acid-base substances, the patterns on UV-printed glass are still prone to local peeling and wear, with relatively average durability, making it more suitable for indoor and low-friction frequency use environments.

3.5 Cost Analysis

The cost structure of UV printing is characterized by "high initial cost and stable unit cost": The early investment is mainly concentrated on equipment and ink. The purchase cost of UV printing equipment (especially high-precision equipment) is much higher than that of screen printing equipment, and the unit price of UV ink is also higher than that of ordinary screen printing ink. During the production process, whether for small-batch or mass production, the ink consumption and equipment energy consumption per unit product are relatively stable, and the unit cost will not decrease significantly with the increase in batch size. Therefore, UV-printed glass is more suitable for small-batch and personalized customization needs, and the batch size has little impact on the unit cost.

4. Comparative Summary of Characteristics between Screen Printing and UV Printing Processes

4.1 Similarities

Both are mainstream glass printing processes, capable of forming patterns or text on the glass surface to meet basic decoration or identification needs;

Both require specific technical means (such as adding curing agents and primer layers) to enhance the combination of ink and the glass surface and improve pattern stability;

Both can be applied to indoor decoration and glass printing of some industrial products (such as home appliances and electronic devices), covering the core scenarios of glass processing to a certain extent.

4.2 Differences

Comparison Dimension | Screen Printing (Screen-Printed Glass) | UV Printing (UV-Printed Glass) |

Process Principle | Screen stencil printing + subsequent curing (high temperature/curing agent) | UV ink spraying + instant UV curing |

Application Scope | Multi-materials (glass, ceramics, etc.), flat/curved glass, mass production | Non-absorbent materials (glass, plastics, etc.), mainly flat glass, small-batch customization |

Color Performance | Single color per print, poor gradient effect | One-time multi-color printing, excellent gradient effect |

Color Adhesion | Strong, wear-resistant, corrosion-resistant, good durability | Relatively weak, requiring primer layer, average durability |

Cost Structure | High stencil-making cost, low unit cost for mass production | High equipment/ink cost, stable unit cost (not affected by batch size) |

5. Recommendations for Process Selection

When choosing between screen-printed glass and UV-printed glass, a comprehensive judgment should be made based on actual needs:

If the demand is for mass and standardized production (such as architectural curtain wall glass and batch home appliance panels), and high pattern durability is required (such as outdoor use and high-frequency friction), the screen printing process is preferred, which can control costs while ensuring product quality;

If the demand is for small-batch and personalized customization (such as custom glass decorative paintings and short-term displays), and high color richness and gradient effect are required (such as complex artistic patterns), the UV printing process is preferred, which can deliver quickly and meet aesthetic needs;

If curved or special-shaped glass printing is involved and there is no specially customized equipment, screen printing should be considered first; if it is flat glass and efficient production is pursued, the process can be flexibly selected according to batch size and color requirements.

6. Outlook on Development Trends

6.1 Screen Printing Process

In the future, it will develop towards the direction of "high precision and automation": On the one hand, by improving stencil-making technology (such as digital stencil-making), the pattern precision will be enhanced, the problem of poor gradient color performance will be solved, and its application in the field of high-precision decoration will be expanded. On the other hand, the automation transformation of production lines will be promoted to reduce manual intervention, shorten the stencil-making and printing cycles, lower the cost of small-batch production, and improve the flexibility of the process.

6.2 UV Printing Process

It will focus on "adhesion improvement and equipment adaptability expansion": Firstly, develop new UV inks and primer layer technologies to enhance the bonding strength between the ink and the glass surface, improve the durability of UV-printed glass, and enable it to adapt to outdoor and high-frequency use scenarios. Secondly, develop UV printing equipment suitable for curved and special-shaped glass to break the current limitation of only printing on flat glass and expand the application range. At the same time, combined with 3D printing technology, explore the realization of three-dimensional pattern printing on the glass surface to further enrich product forms.

6.3 Overall Trend

With the advancement of the concept of green environmental protection, both processes will be upgraded towards "environmental protection": Screen printing will reduce the use of volatile solvent inks and promote water-based inks; UV printing will optimize the energy consumption of UV lamps and develop more environmentally friendly UV inks to achieve "low pollution and low energy consumption" production. In addition, there may be scenarios where the two processes are integrated and applied, such as completing complex color patterns through UV printing first, and then covering a protective layer through screen printing, balancing aesthetics and durability.

UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glass UV-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glassscreen-printed glass