Seven Key Aspects of the Glass Screen Printing Process

In various fields such as architectural decoration, home appliance panels, and automotive glass, screen-printed glass has become a popular product in the market due to its unique pattern presentation and excellent durability. The material properties of glass are highly associated with the technical requirements of the screen printing process. To produce high-quality screen-printed glass, it is essential to firmly control the key points throughout the entire production process. The following will deeply analyze the operating guidelines and quality control focuses of the glass screen printing process from seven core aspects.

1. Pretreatment of Glass Substrate: The Fundamental Guarantee for Screen Printing Effect

The surface condition of the glasssubstrate directly determines the adhesion effect of the ink and the forming quality of the pattern, serving as the first critical checkpoint in the production of screen-printed glass. The surface of untreated glass is often attached with impurities such as dust, oil stains, water stains, and silicon powder residues from the production process. These substances significantly reduce the bonding force between the ink and glass, easily causing defects like pattern peeling, warping, and pinholes.

In the pretreatment stage, first of all, the glass must be cleaned. The common cleaning process is "pre-cleaning - main cleaning - rinsing - drying". In the main cleaning step, alkaline cleaning solution combined with ultrasonic vibration is mostly used to achieve deep cleaning of stubborn stains on the glass surface. For rinsing, deionized water is required to prevent calcium and magnesium ions in the water from forming water spots on the glass surface. Secondly, some screen-printed glass with special requirements also needs surface activation treatment. For example, low-temperature plasma is used to bombard the glass surface to increase its surface tension, allowing the ink to wet and spread better. In addition, it is necessary to inspect the appearance indicators of glass such as flatness and edge chipping to ensure that the glass substrate has no obvious defects, laying a solid foundation for the subsequent screen printing process.

2. Selection and Preparation of Screen Printing Ink: The Core "Pigment" for Screen-Printed Glass

Ink is the core material for pattern presentation and performance guarantee of screen-printed glass. The performance requirements for ink vary significantly for screen-printed glassused in different application scenarios. Firstly, the type of ink should be determined based on the service environment of the glass. For instance, screen-printed glass used for exterior building walls requires outdoor-specific ink with strong weather resistance; screen-printed glass used inside home appliances can use conventional decorative ink; and screen-printed glass used in high-temperature environments must be matched with high-temperature resistant ink.

In the ink preparation process, it is necessary to mix the main agent, curing agent, and thinner in strict accordance with the proportion requirements. The amount of thinner should be accurately controlled: too much thinner will make the ink too dilute, leading to problems such as pattern diffusion and blurred lines during printing; too little thinner will make the ink viscous, which not only increases the wear of the screen but also causes defects like ink shortage and wrinkling in the pattern. At the same time, the prepared ink should be fully stirred evenly to avoid component stratification, and it must be used up within the specified time to prevent ink curing failure. For screen-printed glass with requirements for color accuracy, color sample comparison should be conducted in advance to ensure that the printed color is consistent with the design standard.

3. Screen Production and Installation: The "Mold" for Screen-Printed Glass Patterns

The screen is a key carrier for pattern formation of screen-printed glass, and its quality directly affects the printing accuracy. For screen production, first, a screen with an appropriate mesh count should be selected based on the fineness of the pattern: high-mesh screens are suitable for fine patterns, while low-mesh screens can be used for large-format patterns with thick lines. In the photosensitive adhesive coating process, it is necessary to ensure that the coating is uniform and has an appropriate thickness. Excessive thickness will reduce the clarity of the pattern, while insufficient thickness is prone to pinholes and sand holes.

The exposure process is the core of screen production, which requires precise control of exposure time and light source intensity. Insufficient exposure will lead to fuzzy pattern edges and film peeling, while excessive exposure will cause some areas of the pattern to fail to develop. The finished screen should be strictly inspected to confirm that there is no pattern deformation or damage before installation and debugging. During installation, the parallelism between the screen and the glass substrate must be ensured, and the distance between the screen and the glass (i.e., screen distance) should be adjusted properly. Excessive screen distance is likely to cause pattern deformation, while insufficient screen distance will result in excessive contact between the screen and the glass, leading to smudging and screen damage. In addition, the screen should be fixed firmly to avoid shaking during the printing process, which may affect the pattern consistency of screen-printed glass.

4. Printing Parameter Debugging: The Key Control for Screen-Printed Glass Formation

The parameter setting in the printing process is a core step that determines the finished product quality of screen-printed glass, and key parameters such as the squeegee, printing speed, and pressure need to be focused on adjusting. The angle of the squeegee is generally controlled between 45° and 60°. An excessively small angle will result in insufficient ink transfer, while an excessively large angle is likely to scratch the screen. Meanwhile, a squeegee with appropriate hardness should be selected according to the ink properties and pattern requirements: soft squeegees are suitable for printing on irregular glass surfaces, and hard squeegees are more suitable for high-precision pattern printing on flat glass.

The printing speed should match the fluidity of the ink and the mesh count of the screen. Excessively fast printing speed will leave insufficient time for the ink to fully fill the mesh holes, resulting in ink shortage in the pattern; excessively slow printing speed will cause ink accumulation on the screen, leading to pattern edge blurring. The printing pressure should be kept uniform and stable. Excessively high local pressure is prone to leaving squeegee marks on the glass surface, while insufficient pressure will result in insufficient ink transfer and uneven pattern color. In addition, the positioning of the printing table should be adjusted according to the size and shape of the glassto ensure accurate placement of the glass, avoiding problems such as pattern offset and inaccurate overprinting. Especially in the production of multi-color overprinted screen-printed glass, the parameters for each overprinting must be highly consistent.

5. Glass Positioning and Conveying: Ensuring the Consistency of Screen-Printed Glass

The positioning accuracy and conveying stability of glass during the printing process are important prerequisites for realizing mass production of high-quality screen-printed glass. In the positioning process, special positioning jigs such as positioning pins and positioning blocks should be set according to the size and shape of the glass to ensure that each piece of glass is placed at the same reference position, preventing pattern position deviation caused by glass offset. For special-shaped glass, customized positioning tools are also required to ensure that it does not shake or shift during the printing process.

In the conveying process, suitable conveying equipment should be selected, and the conveying speed and the tightness of the conveyor belt should be adjusted according to glass of different thicknesses and sizes. During conveying, friction and collision on the glasssurface should be avoided to prevent physical damage such as scratches and edge chipping on the glass. At the same time, the flatness of the conveying track should be inspected regularly to prevent the glass from tilting during conveying, which may affect the subsequent printing and curing processes. For mass-produced screen-printed glass, a visual positioning system can also be installed to real-time calibrate the position of the glass through image recognition technology, further improving the positioning accuracy.

6. Curing Treatment: The Core Step for Ink Adhesion on Screen-Printed Glass

The printed screen-printed glass must undergo curing treatment to ensure firm bonding between the ink and the glass. The curing method should be selected according to the type of ink. For solvent-based inks, natural air-drying or low-temperature drying can be adopted to fully volatilize the solvent in the ink; for UV-curable inks, ultraviolet irradiation is required to make the ink complete cross-linking and curing in a short time; and for high-temperature curing inks, baking must be carried out in a special oven according to the specified temperature and time.

The parameter control in the curing process is crucial. Excessively low temperature or insufficient time will result in incomplete ink curing, and the pattern on the screen-printed glass is prone to peeling and fading; excessively high temperature or too long time may cause the glass to burst, and at the same time, it will lead to ink discoloration and embrittlement. After curing, the screen-printed glassneeds to be cooled. The cooling process should be slow and stable to avoid internal stress in the glass caused by excessive temperature difference, which may affect the overall strength of the screen-printed glass.

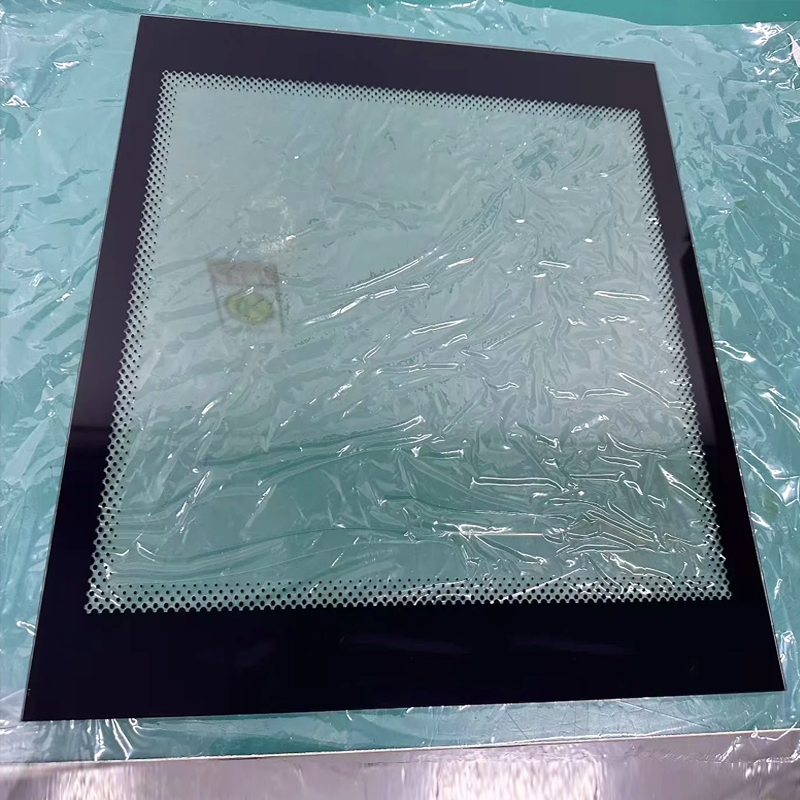

7. Finished Product Inspection and Post-Processing: The Final Line of Defense for Screen-Printed Glass Quality

Finished product inspection is the final quality checkpoint for screen-printed glass before leaving the factory, which requires comprehensive inspection from multiple dimensions such as appearance and performance. Appearance inspection mainly focuses on checking whether the pattern of screen-printed glass has defects such as offset, blurriness, ink shortage, and wrinkling, whether the glass surface has problems such as scratches, bubbles, and impurities, and at the same time, verifying whether the color and size of the pattern are consistent with the design standard.

Performance inspection should be carried out according to the usage requirements of screen-printed glass. For example, the friction resistance test is used to inspect the adhesion firmness of the ink; the weather resistance test is used to evaluate the anti-aging ability of the pattern by simulating the outdoor environment; the chemical resistance test is used to detect the stability of screen-printed glass in environments such as acid and alkali. For qualified screen-printed glass after inspection, necessary post-processing is also required, such as polishing the edges of the glass to remove burrs and chipping, cleaning the surface to remove residual ink and dust, and for screen-printed glass with special protection requirements, a protective film can be added to prevent scratches during transportation and installation. Unqualified screen-printed glass after inspection should be classified for processing: those that can be reworked should be corrected in a timely manner, and those that cannot be reworked should be scrapped, ensuring that the screen-printed glass leaving the factory meets the quality standards.